Hey there! If you’re running a small business and thinking about stepping up your game with some in-house manufacturing, you’re in the right place. CNC machines can be a total game-changer, making your production more precise and efficient. Let’s break it down and see what works best for you.

First things first, why should you even bother with the right CNC machine? Simple. These powerful tools automate tedious tasks like cutting, milling, and engraving, which translates to more consistent quality, precision machining, and less time wasted. Whether you’re into custom furniture, knife handles, or intricate designs, CNC can handle it all.

Increased Precision: CNC machines are known for their high precision and consistency, which is crucial for maintaining quality standards, especially for small business owners.

Time Efficiency: Automating repetitive tasks can save significant time, allowing you to focus on other important aspects of your business. This is where CNC routers shine. Automated manufacturing further enhances time efficiency by streamlining production processes and increasing productivity.

Versatility: CNC machines can work with various materials such as wood, metal, and plastic, making them suitable for diverse applications.

Cost-Effectiveness: While the initial investment might be high, the long-term benefits of reduced labor costs and increased productivity can outweigh the costs.

1. Workflow Efficiency: If you’re producing batches of the same item, a CNC machine is a no-brainer due to its precision cutting capabilities. But if you’re doing a lot of unique, custom designs, you might find the CAD/CAM software a bit time-consuming. (Agilemaking can help you with this!)

2. Machine Size: Many people ignore their size restrictions when looking for the right CNC machine. Smaller models like the Woodworker or Journeyman are great for knife scales and other small projects. For small business CNC machines, compact size is crucial to optimize limited workshop spaces without compromising functionality or performance. Think about what you need to make and pick accordingly.

3. Software: Get comfy with CAD/CAM software before you dive in. FreeCAD, VCarve Pro, and Rhino are good starting points. Additionally, CNC control software is critical as it manages the movement of machining tools and equipment. The learning curve can be steep, but it’s worth it.

4. Budget: Expect to spend more than you initially think. A solid setup, including all the necessary accessories, might set you back closer to $10k.

1. Expansive Work Area: More space means you can handle bigger projects or multiple small ones at once. Less repositioning, more efficiency. High-speed machining can further enhance efficiency and productivity by reducing cycle times and improving surface finishes.

2. Stepper Motors: These provide super accurate control, which is key for high-quality output.

3. User-Friendly Software: Make sure the software matches your needs. Whether it’s 2-axis, 3-axis, or multi-axis control, pick software that maximizes your machine’s capabilities.

4. Compact CNC Milling Machine: A compact CNC milling machine is ideal for small business environments. It enhances workflow and efficiency, offering customization options for various applications like metal fabrication and woodworking. Its technical features ensure precision and stability in the manufacturing process.

5. Benchtop Milling Machine: The CNC Masters Jr. Benchtop Milling Machine is a cost-effective and high-quality option for small businesses and hobbyists. It is perfect for limited workspace settings, providing compact and efficient machining solutions.

Incorporating insights from the Reddit CNC community, many users emphasize the importance of starting small and gradually scaling up. It is also crucial to select machines that can handle both primary and secondary CNC machining applications, particularly for small businesses and hobbyists. Beginners often find the Sainsmart Genmitsu 3018-PROver to be a perfect entry-level machine due to its affordability and ease of use. However, as your skills and production needs grow, upgrading to more robust machines like Sainsmart Genmitsu 3030-PROver becomes crucial. Additionally, CNC machining centers can be highly beneficial for small businesses looking to scale up their production capabilities.

Now that we’ve covered why a CNC machine is a great investment for your small business and what key factors to consider, it’s time to reveal the top picks. After thorough research and considering various user reviews, we’ve identified the best CNC machines that can significantly enhance your production efficiency and output quality. CNC machining centers are among the top picks for small businesses due to their versatility and efficiency.

Let’s dive in and explore these top-rated options:

All-Aluminum Benchtop CNC Router

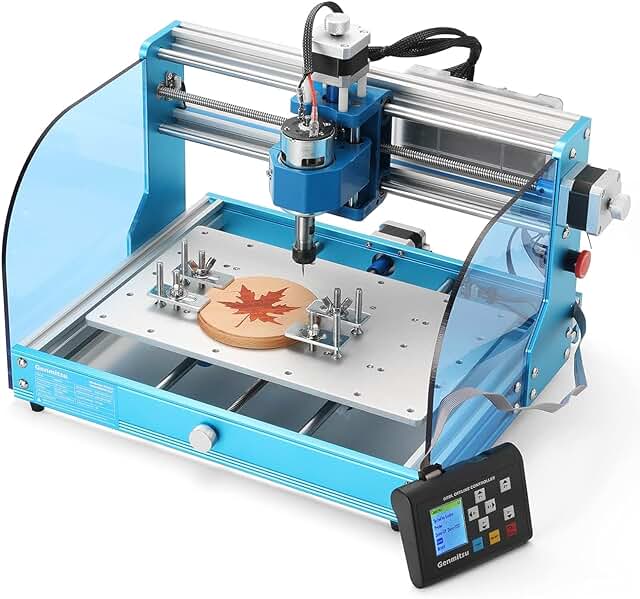

Elevate your metalworking game with the Genmitsu 3030-PROVer MAX Desktop CNC Router, a cutting-edge precision tool engineered for unrivaled accuracy and power.

1. Sainsmart Genmitsu 3030-PROver: Featuring a robust aluminum frame and reinforced design, it offers enhanced durability and stability for precise machining.

Better Stability and Accuracy

This high-performance router is designed for efficiency and reliability, making it an essential addition to your workshop.

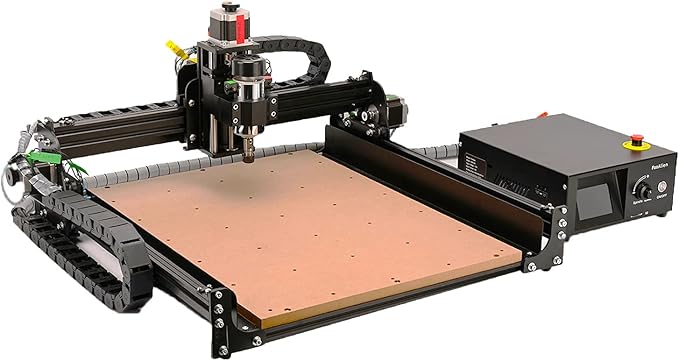

2. FoxAlien CNC Router Machine XEPRO: a popular choice for both enthusiasts and professionals seeking a reliable and adaptable CNC router.

Versatile and Precise tool

The robust, all-aluminum construction enhances durability and rigidity, providing a more stable machining experience.

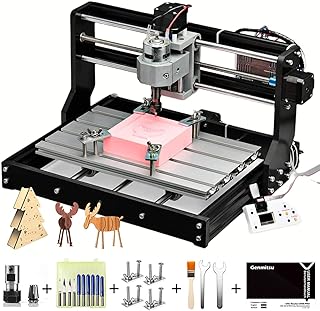

3. Genmitsu CNC 3018 PRO Router Kit: offers a cost-effective entry point for those interested in CNC machining, making it accessible to hobbyists and beginners.

Affordable Precision

Engineered for precise and stable operations, the Genmitsu 3018-PROVer offers a perfect blend of affordability and performance.

4. Genmitsu 3018-PROVer: A Precision Tool for Your Workshop

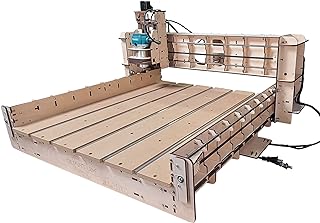

Large-Scale Woodworking

This machine stands out with its large cutting area and rigid structure, ideal for woodworkers looking to tackle larger projects.

5. BobCNC Quantum CNC Router Kit: Ultimate Performance for Woodworkers

High Precision for Intricate Designs

The 4040-XE is perfect for detailed and intricate projects, offering exceptional control and accuracy for advanced users.

6. FoxAlien CNC Router 4040-XE: A Powerhouse for Intricate Designs

Advanced CNC Machining

Shapeoko 4 takes performance to the next level with enhanced rigidity and an expansive work area, perfect for complex projects.

7. Shapeoko 4 CNC Router: Built for Serious Hobbyists and Professionals

Versatility and Power

Designed with versatility in mind, the LongMill MK2 caters to a wide range of materials and applications, making it an all-around workhorse.

8. LongMill MK2 CNC Router: A Versatile Tool for Makers

According to industry reviews on LinkedIn, 2024 has seen a surge in demand for CNC machines with advanced features such as automatic tool changers (ATCs) and expansive work areas. Advanced CNC machines significantly impact manufacturing processes by enhancing precision and consistency in production environments. These features significantly enhance productivity by reducing manual intervention and allowing for more complex and varied tasks to be performed seamlessly.

These are a game-changer. They switch tools automatically, saving you time and ensuring precision.

In recent years, there has been significant progress in stepper motor technology, leading to the development of more efficient and powerful motors that are now becoming the industry standard. These advancements not only enhance the precision and reliability of CNC machines but also contribute to smoother and quieter operation. Alongside this, the integration of intuitive, user-friendly software interfaces has made these systems more accessible than ever before. This combination of cutting-edge motors and easy-to-use software ensures that even those who are new to CNC machining can achieve high levels of accuracy and control with minimal effort.

Whether you are a hobbyist or a professional, these innovations make operating complex machinery simpler and more efficient, allowing you to focus on creativity and production rather than the technicalities of machine control.

Think about what you really need. Consider the learning curve of the software, your workflow, and your budget. Make an informed decision, and you’ll end up with CNC machinery that’s perfect for your small business.

Factors to Consider:

Type of Projects: What kind of products will you be making? Choose a machine that fits your specific production needs.

Space Availability: Ensure you have enough space for the machine and its operation.

Future Expansion: Consider machines that allow for upgrades or expansion as your business grows.

Support and Training: Look for manufacturers that offer good customer support and training programs. CNC machining services can provide valuable support and training for small business owners.

To maximize your investment, consider the following:

1. Training and Support: Invest in proper training for your team to ensure they can fully leverage the capabilities of your CNC machine. Many manufacturers offer comprehensive training programs and customer support. Additionally, CNC machining services can help small businesses maximize their investment by providing expert assistance and resources.

2. Maintenance and Upgrades: Regular maintenance is key to prolonging the lifespan of your CNC machine. Additionally, keep an eye on technological advancements and consider periodic upgrades to stay competitive.

3. Diversification: Use your CNC machine to diversify your product offerings. From intricate engravings to large-scale manufacturing, the versatility of CNC technology can open up new revenue streams for your business.

Choosing the best CNC machine for your small business involves careful consideration of your specific needs, budget, and long-term goals. Precision machining is crucial when selecting the right CNC machine, as it ensures high-quality and accurate production. Whether you’re just starting out or looking to expand your production capabilities, there’s a CNC machine out there that’s perfect for you. The initial investment might be a bit steep, but the benefits are totally worth it.

Making money with a CNC router is achievable with the right strategies and a focus on quality and customer satisfaction. The versatility of CNC routers allows for a wide range of applications, from intricate custom sign making to producing unique furniture and home decor items that stand out in the market. Specializing in custom sign making can attract businesses and individuals seeking personalized branding and decorative solutions. On the other hand, crafting bespoke furniture and home accessories can cater to niche markets that value handcrafted and unique designs.

Offering prototyping and small-scale manufacturing services opens doors to collaborations with inventors, startups, and small businesses that need precise prototypes and limited production runs. This not only builds a strong client base but also positions you as a reliable partner in the product development process. Additionally, the woodworking and engraving market allows you to create detailed, high-quality products like custom cabinetry, engraved gifts, and decorative wood panels that appeal to a broad audience.

Educational products and DIY kits represent another profitable avenue. By designing educational tools, craft kits, and DIY models, you can tap into the growing market of hands-on learning and hobby enthusiasts. These products not only serve educational purposes but also provide enjoyable and engaging activities for various age groups.

Finally, custom CNC router work for local businesses can open up additional revenue streams by providing unique and valuable solutions to businesses in your community. From retail displays to promotional items and interior decor, the possibilities are vast.

No matter which area you choose to focus on, the key to success lies in leveraging your CNC router’s capabilities to deliver high-quality, precision-made products that meet market demands. By continually innovating and adapting to customer needs, you can establish a profitable business and achieve sustained growth. Start leveraging your CNC router today, and turn your creativity and skills into a profitable venture that stands out in the competitive marketplace.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!