Computer-Aided Design (CAD) is utilized by a wide range of professionals across various industries. The versatility and precision of CAD make it an essential tool for:

These professionals rely on CAD to enhance their design processes, improve accuracy, and streamline their workflows.

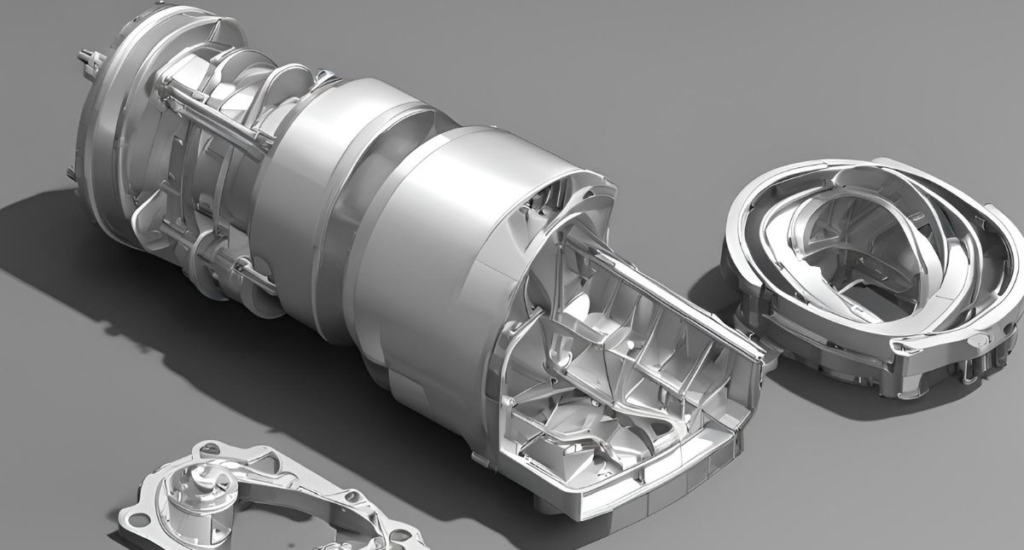

CAD is indispensable in the engineering sector for creating detailed schematics and prototypes. Architects use CAD to develop intricate building plans and ensure structural integrity. Industrial designers benefit from CAD by visualizing and modifying product designs efficiently.

Ultimately, CAD’s widespread adoption highlights its importance in producing high-quality, precise, and innovative designs.

CAD technology offers numerous advantages that significantly improve the design process. Firstly, it increases productivity by allowing designers to create and modify designs quickly and efficiently. This speed and flexibility enable shorter project timelines and faster iterations.

Another key benefit of CAD is its ability to reduce errors. Traditional hand-drawn designs are prone to mistakes, whereas CAD provides tools for precise measurements and error-checking, ensuring higher accuracy in the final product. This precision leads to better quality outcomes and fewer revisions.

Moreover, CAD enhances information sharing among team members. Digital designs can be easily shared and collaborated on, making it simple for multiple designers to work together on a single project. This collaborative nature of CAD fosters innovation and creativity within design teams.

CAD plays a pivotal role in modern manufacturing by providing precise and detailed designs that are essential for production. Manufacturers rely on CAD to create exact specifications that guide the entire manufacturing process, ensuring consistency and quality in the final products.

Another critical aspect of CAD in manufacturing is its ability to streamline workflows. CAD allows for the integration of design and manufacturing processes, reducing the time and effort required to transition from concept to production. This efficiency is crucial in meeting market demands and maintaining competitiveness.

Moreover, CAD facilitates innovation and customization. With CAD, manufacturers can easily modify designs to meet specific customer requirements or adapt to new trends. This flexibility enables manufacturers to offer unique and tailored products, enhancing customer satisfaction and loyalty.

Computer-Aided Design (CAD) is a technology that revolutionized the way we approach design and drafting. It involves the use of computer software to create, modify, analyze, and optimize designs. CAD is essential in various fields including engineering, architecture, and industrial design.

The precision and efficiency provided by CAD have made it an indispensable tool in modern design practices.

CAD software enables designers to visualize their concepts in 2D or 3D, making it easier to identify potential issues and make necessary adjustments early in the design process. This capability not only saves time but also reduces costs associated with physical prototyping.

Additionally, CAD integrates seamlessly with other digital tools and technologies, such as CNC machines and 3D printers, further streamlining the transition from design to production. This integration is crucial for maintaining competitiveness in today’s fast-paced manufacturing environment.

CAD significantly enhances productivity by automating repetitive tasks. Designers can use CAD software to create templates and libraries of standard components, reducing the time spent on manual drawing and allowing them to focus on more creative aspects of design.

The ability to quickly iterate and modify designs is another major productivity booster. CAD software enables designers to make changes swiftly and efficiently, without the need to start from scratch. This flexibility is especially valuable in complex projects where frequent revisions are common.

Furthermore, CAD improves collaboration and communication within design teams. Digital designs can be easily shared and reviewed by multiple stakeholders, facilitating better coordination and decision-making. This collaborative environment helps to ensure that the final design meets all requirements and expectations.

One of the primary benefits of using CAD technology is its ability to minimize errors in the design process. CAD provides tools and features that help ensure accuracy and precision in every aspect of a design.

These features significantly reduce the likelihood of mistakes and discrepancies.

Automated error checking in CAD software helps identify potential issues early in the design process, allowing designers to address them before they become costly problems. Precise measurements and dimensions ensure that every component fits together perfectly, reducing the risk of assembly errors.

Additionally, CAD software can simulate real-world conditions and test designs under various scenarios. This capability allows designers to identify and rectify potential issues, ensuring that the final product performs as intended. Consistent documentation and version control further enhance accuracy by maintaining a clear record of design changes and updates.

Designers have access to a variety of CAD software and tools that cater to different needs and industries. Some of the most popular CAD software includes:

Each of these tools offers unique features and capabilities that make them suitable for specific design requirements.

AutoCAD is widely used for 2D and 3D drafting in architecture and engineering. SolidWorks is favored by mechanical engineers for its robust simulation and modeling tools. CATIA is a powerhouse for complex product design in aerospace and automotive industries. Rhino excels in freeform surface modeling, and Fusion 360 is popular for its cloud-based collaboration features.

Choosing the right CAD software depends on the specific needs of the project and the industry in which it is used. Familiarity with multiple CAD tools can also enhance a designer’s versatility and skill set.

CAD technology plays a crucial role in ensuring high-quality products by allowing for precise and accurate designs. It enables designers to create detailed and exact specifications that meet stringent quality standards.

One of the significant advantages of CAD is its ability to simulate and test designs under real-world conditions. This testing helps identify potential flaws and areas for improvement before the actual production, ensuring that the final product is of the highest quality.

Furthermore, CAD provides the tools needed for consistent documentation and version control, allowing designers to track changes and maintain a clear history of modifications. This consistency ensures that all design updates are accurately reflected in the final product, maintaining the integrity and quality of the design.

One of the key benefits of CAD is its ability to enhance information sharing among team members. Digital designs can be easily shared and collaborated on, making it simple for multiple designers to work together on a single project.

This collaborative nature of CAD fosters innovation and creativity within design teams. By allowing real-time sharing and editing of designs, team members can quickly incorporate feedback and make necessary adjustments, ensuring that the final design meets all requirements and expectations.

Moreover, CAD software often includes tools for commenting and markup, which facilitate clear communication and coordination among team members. This enhanced communication helps avoid misunderstandings and ensures that everyone is on the same page throughout the design process.

A CAD technician plays a vital role in the design and manufacturing industries. They are responsible for creating detailed technical drawings and plans using CAD software. These drawings are used to guide the production and construction of various products and structures.

Key responsibilities of a CAD technician include:

CAD technicians must have a strong understanding of design principles and be proficient in using CAD software. Their work is essential in translating conceptual ideas into tangible products and structures.

CAD is used across a wide range of industries due to its versatility and precision. Some of the key applications of CAD include:

In architecture, CAD is used to create detailed blueprints and ensure the structural integrity of buildings. Engineers use CAD to develop technical schematics and test prototypes, while industrial designers rely on CAD to visualize and refine their product designs.

Graphic designers use CAD to develop intricate illustrations and visual concepts, and fashion designers use it to create clothing patterns and accessories. The widespread use of CAD in these industries highlights its importance in modern design and manufacturing processes.

CAD has come a long way since its inception, evolving from simple 2D drafting tools to sophisticated 3D modeling and simulation software. This evolution has significantly improved the efficiency and accuracy of the design process.

One of the key trends in CAD is the integration of cloud-based collaboration tools. These tools allow designers to work together in real-time, regardless of their physical location, enhancing collaboration and productivity.

Another important trend is the use of artificial intelligence (AI) and machine learning in CAD software. These technologies can automate routine tasks, provide intelligent design suggestions, and optimize designs based on specific criteria.

Additionally, the rise of virtual reality (VR) and augmented reality (AR) in CAD is transforming the way designers visualize and interact with their designs. These technologies provide immersive experiences that enable designers to explore and refine their designs in new and innovative ways.

Selecting the appropriate CAD software is crucial for achieving the best results in your design projects. Here are some factors to consider when choosing CAD software:

By considering these factors, you can select the CAD software that best meets your needs and enhances your design process.

CAD technology can have a significant impact on small businesses by improving their design processes and increasing efficiency. Small businesses can benefit from CAD in several ways:

By adopting CAD technology, small businesses can compete more effectively in the market and offer high-quality products that meet customer demands.

CAD software uses various file formats to store and share design data. Some of the most common CAD file formats include:

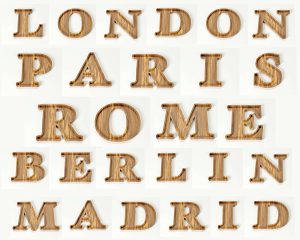

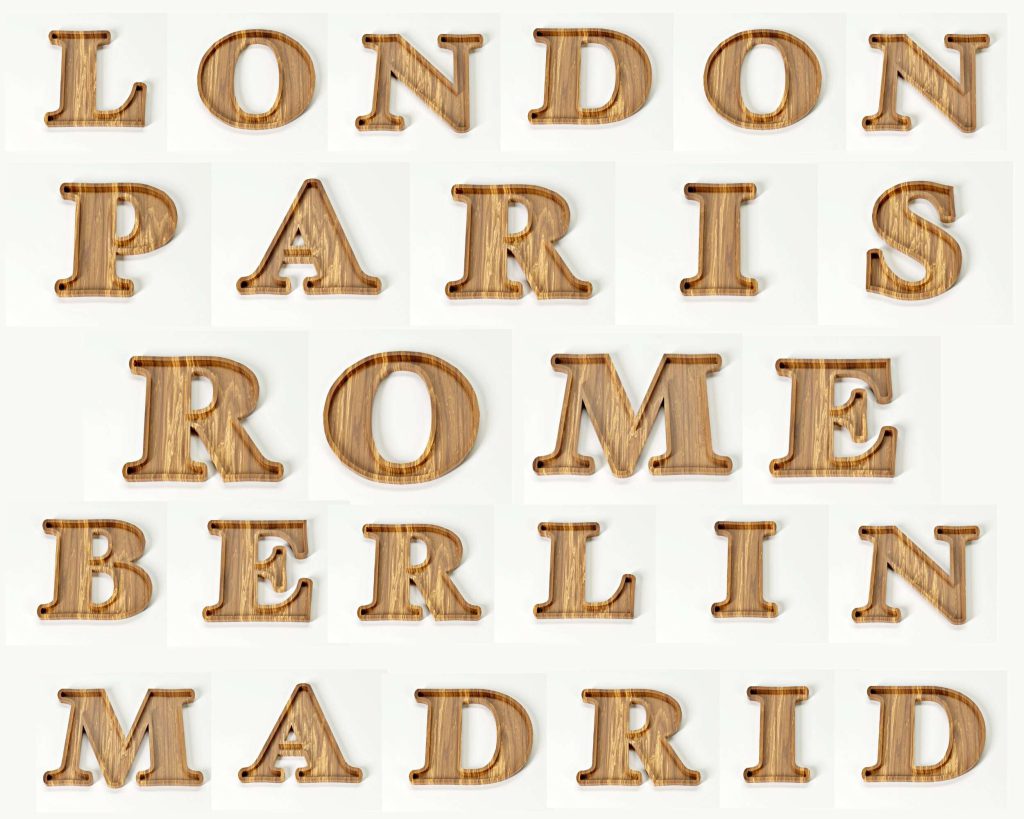

Our CNC Letter Boards are a collection of intricately designed wood templates compatible with wood routers. Each file in this set contains a unique router typeface that allows you to create stunning alphabet-inspired grill planks for your BBQ gatherings. Transform your outdoor cookouts with these finely crafted designs, making your BBQ experience truly one-of-a-kind. Moreover, imagine crafting …

Understanding these file formats is essential for ensuring compatibility and efficient data exchange between different CAD systems.

For beginners, starting with CAD can seem daunting, but with the right approach, it can be a rewarding experience. Here are some tips to help you get started:

By following these tips, you can build a strong foundation in CAD and improve your design capabilities.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!