Are you a craft maker looking to add a CNC machine to your workshop? Or perhaps you’re an entrepreneur aiming to start an aluminum model business? Either way, you’ve come to the right place. In this guide, we’ll explore the best CNC machines for aluminum, focusing on the versatility, properties, and applications of aluminum material. This will help you make an informed decision that balances quality with value for money.

Before we dive into specific machines, let’s briefly cover what makes CNC machining ideal for aluminum:

Precision: CNC machines offer incredibly tight tolerances, perfect for aluminum’s versatility. The right cutting tool is essential for achieving this precision.

Efficiency: Automated processes mean faster production times and consistent results. Aluminum alloys have a high machinability rating, which facilitates fast and efficient processing.

Complexity: CNC allows for intricate designs that would be challenging or impossible by hand.

Corrosion Resistance: Certain aluminum alloys, such as 6061 and 5052, exhibit high corrosion resistance, making them suitable for critical applications in industries like aerospace and marine.

Aluminum alloys offer numerous benefits that make them ideal for CNC machining applications. One of the standout features is their high strength-to-weight ratio, which is particularly advantageous in industries like aerospace and automotive where reducing weight without compromising strength is crucial. This property allows for the creation of lightweight yet durable components, enhancing overall performance and efficiency.

Another significant advantage is the excellent machinability of aluminum alloys. These materials are easy to machine, boasting a high machinability rating that facilitates fast and efficient processing. This means you can achieve precise cuts and intricate designs with minimal effort, making aluminum a favorite among CNC machinists.

Corrosion resistance is another key benefit. Many aluminum alloys possess natural corrosion resistance, making them suitable for applications exposed to harsh environments. This property ensures longevity and reliability, even in challenging conditions.

Aluminum alloys also offer high electrical conductivity, making them ideal for applications requiring efficient electrical transmission. Additionally, they can be anodized or coated with various finishes to enhance their appearance and performance, providing both functional and aesthetic benefits.

Lastly, aluminum alloys are highly recyclable, making them an environmentally friendly choice for CNC machining applications. This recyclability not only reduces waste but also contributes to sustainable manufacturing practices.

When selecting a CNC machine for aluminum work, consider these crucial aspects, including the choice of the most popular aluminum alloy for your specific needs:

Machine rigidity: Aluminum requires a sturdy machine to prevent vibrations and ensure accuracy.

Spindle speed: Higher speeds are generally better for aluminum, typically ranging from 10,000 to 30,000 RPM.

Coolant system: Proper cooling is essential when working with aluminum to prevent heat buildup.

Software compatibility: Ensure the machine works with your preferred CAD/CAM software.

Work area: Consider the size of projects you’ll typically handle.

Aluminum alloy selection: Choosing the right aluminum alloy, such as the high-strength 7075 or the highly machinable 6061, is crucial for achieving the desired properties and performance in aerospace and manufacturing applications.

Let’s explore some top contenders in different price ranges:

Pros:

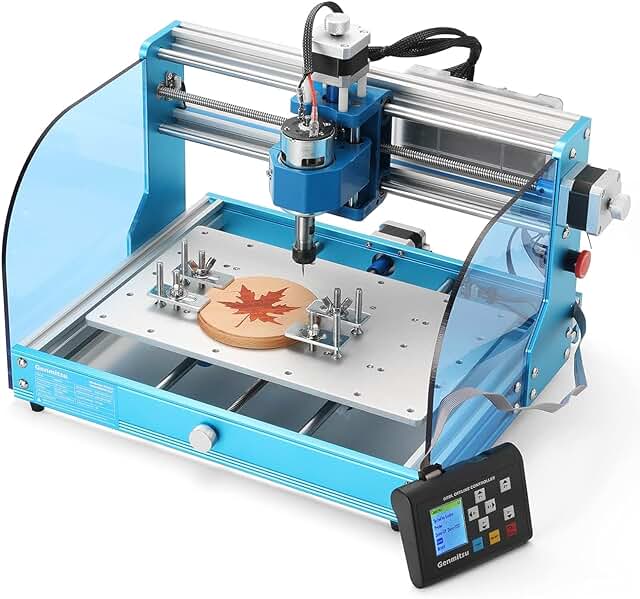

Affordable entry point for hobbyists

Compact size ideal for small workshops

User-friendly for beginners

Cons:

Limited work area (300x180x45mm)

May struggle with harder aluminum alloys

The Genmitsu 3018-PROVer V2 is an excellent starting point for those new to CNC machining. While it’s not specifically designed for aluminum, it can handle softer alloys for small projects. It’s a great way to learn the basics before investing in a more powerful machine.

Visit the manufacturer’s site, the eBay offer, and the Amazon offer here.

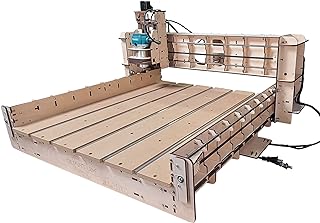

Pros:

Larger work area (610x610x76mm)

Sturdy construction for better stability

Compatible with various routing bits

Cons:

Requires assembly

May need upgrades for optimal aluminum performance

The BobsCNC Quantum offers a significant step up in terms of capability. Its robust frame provides better stability for aluminum work, and the larger work area allows for bigger projects. With some tweaks and the right tooling, it can handle a wide range of aluminum machining tasks, including intricate geometries and cnc machined aluminum parts for automotive and aerospace applications.

Visit the manufacturer’s site, and the Amazon offer here.

Pros:

Heavy-duty construction ideal for aluminum

Large work area (760x760x102mm)

High-power spindle options available

Cons:

Higher price point

Requires more space

For those serious about aluminum machining, the LongMill MK2.5 is a top contender. Its rigid construction and powerful spindle options make it well-suited for a variety of aluminum alloys. The machine’s ability to work with high-quality aluminum alloys, known for their natural corrosion resistance, ensures durability and performance in various atmospheric conditions. This makes it suitable for both hobbyist projects and light commercial work with ease.

Visit the manufacturer’s site, and the Amazon offer here.

CNC machining techniques for aluminum involve using computer-controlled machines to remove material from an aluminum workpiece, creating precise and complex shapes. Here are some common techniques:

CNC Milling: This technique uses a rotating cutting tool to remove material from the aluminum workpiece. CNC milling is ideal for creating complex shapes and designs, offering high precision and versatility. It’s commonly used for producing parts with intricate geometries and tight tolerances.

CNC Turning: In CNC turning, a single-point cutting tool removes material from the rotating aluminum workpiece. This technique is perfect for creating cylindrical shapes and parts, such as shafts and rods. CNC turning ensures smooth finishes and precise dimensions.

CNC Drilling: CNC drilling involves using a rotating cutting tool to create holes in the aluminum workpiece. This technique is essential for making holes for fasteners or other components, ensuring accurate placement and consistent diameters.

CNC Grinding: CNC grinding uses a rotating grinding wheel to remove material from the aluminum workpiece, creating high-precision surfaces and finishes. This technique is often employed for achieving smooth, polished surfaces and tight tolerances.

Each of these techniques offers unique advantages, making them suitable for different applications and requirements in aluminum CNC machining.

Router bits for aluminum CNC machining are designed to efficiently cut and shape aluminum alloys, ensuring precision and durability. Here are some common types of router bits used in aluminum CNC machining:

Carbide-Tipped Router Bits: These bits are designed for high-speed machining of aluminum alloys. They offer excellent wear resistance and long tool life, making them ideal for demanding applications. Carbide-tipped bits maintain sharpness and precision, even under high-speed conditions.

High-Speed Steel Router Bits: High-speed steel (HSS) router bits are suitable for general-purpose machining of aluminum alloys. They provide good wear resistance and moderate tool life, making them a versatile choice for various applications. HSS bits are cost-effective and reliable for everyday machining tasks.

Diamond-Coated Router Bits: These bits are designed for high-precision machining of aluminum alloys. The diamond coating offers exceptional wear resistance and long tool life, making them perfect for applications requiring fine finishes and tight tolerances. Diamond-coated bits are ideal for intricate and detailed work.

Specialty Router Bits: Specialty router bits are tailored for specific applications, such as cutting complex shapes or creating high-precision surfaces. They offer excellent performance and long tool life, ensuring optimal results for specialized tasks. These bits are designed to meet the unique demands of advanced machining projects.

4.5 out of 5 stars

The Freud 87-208 8 Piece CNC Router Bit General Purpose Set is a versatile and high-quality collection of router bits designed for use with CNC machines. This set includes a variety of bit shapes and sizes, allowing for a wide range of cutting and shaping applications. Each bit is made from durable carbide for long-lasting performance and precision cutting. Whether you're a professional woodworker or a hobbyist, this set is perfect for creating intricate designs and smooth finishes on a variety of materials. Upgrade your CNC routing capabilities with the Freud 87-208 set. Just for: $127.81

When selecting router bits for aluminum CNC machining, consider factors such as the type of aluminum alloy being machined, the desired surface finish, and the machining speed and feed rates. Choosing the right bit ensures efficient and precise machining, enhancing the quality of your aluminum parts.

Use the right cutting tools: Opt for endmills specifically designed for aluminum. Selecting the appropriate cutting tool, such as those made from carbide or PCD, is crucial for achieving precision and efficiency in drilling, milling, and turning operations.

Optimize your feed rates: Generally, faster feeds work better for aluminum to prevent heat buildup.

Apply proper lubrication: A good coolant or cutting fluid is crucial for clean cuts and tool longevity.

Start with easier alloys: If you’re new to aluminum machining, begin with softer aluminum alloys like 6061, which offer excellent machinability, before tackling harder ones like 7075.

Invest in quality workholding: Secure clamping is essential for precise aluminum cuts.

4.4 out of 5 stars

The POWERTEC 1PK Toggle Clamp is a heavy-duty clamp designed for securely holding materials in place during woodworking, metalworking, or any other type of project. With a 500lbs holding capacity, this clamp can handle even the toughest jobs. The 305CM quick release feature allows for easy and efficient operation, saving you time and effort. Whether you're a professional tradesperson or a DIY enthusiast, the POWERTEC Toggle Clamp is a reliable tool that will help you get the job done with precision and ease. Just for: $11.72

Before making your purchase, ask yourself:

What types of projects will you be working on most frequently? Consider if you will be working with versatile aluminum material, known for its properties and applications in CNC machining.

Do you have the space and budget for your chosen machine?

Are you prepared for the learning curve that comes with CNC machining?

Do you have a market for aluminum products if you’re starting a business?

Choosing the right CNC machine for aluminum work is a balance between your needs, budget, and expertise. If you’re just starting out, consider beginning with an entry-level machine like the Genmitsu 3018-PROVer V2 to learn the ropes. As your skills and requirements grow, you can upgrade to more powerful options like the BobsCNC Quantum or LongMill MK2.5.

Remember, the best machine for you is one that fits your specific needs and allows you to grow. Don’t be afraid to start small and work your way up – the world of CNC aluminum machining is exciting and full of possibilities! Utilizing aluminum material, especially various grades of aluminum alloy like 7075 for its high strength and 6061 for its excellent machinability, can significantly enhance your CNC machining projects.

Ready to explore CNC machines for your aluminum projects? Check out our curated selection of CNC tools and accessories at Agilemaking.com. We’re here to help you find the perfect fit for your workshop or business!

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!