Are you an aspiring woodworking enthusiast on a quest for the perfect CNC router? Look no further! In this comprehensive guide, we will walk you through the essential factors to consider when selecting the ideal CNC router for your woodworking projects. Whether you are a seasoned craftsman or just starting out, finding the right machine is crucial to achieving precision, efficiency, and outstanding results.

We understand that the world of CNC routers can be overwhelming with numerous options available in the market. That’s why we have compiled this ultimate guide to simplify your decision-making process. From machine types and sizes to cutting capabilities and software compatibility, we will cover it all.

A CNC router table is an essential tool for both professional woodworking and hobbyist projects, offering versatility, precision, and efficiency in cutting. It is widely used in applications such as furniture making and cabinetry, accommodating users ranging from enthusiastic hobbyists to experienced professionals.

But that’s not all! We will also provide expert tips and insights from experienced woodworkers to help you make an informed choice. Whether you are seeking versatility, speed, or affordability, this guide will equip you with the knowledge needed to find the CNC router that best suits your unique woodworking needs. Embark on your woodworking journey with confidence and take your creations to new heights with the perfect CNC router by your side.

When it comes to CNC routers for woodworking, there are several distinct types to choose from. Understanding the unique characteristics and applications of each type is crucial in selecting the right machine for your projects.

One of the most common types of CNC routers for woodworking is the benchtop model. These compact and lightweight machines are designed to sit on a workbench or table, making them an excellent choice for hobbyists or small workshops with limited space. Despite their smaller work area, benchtop CNC routers are capable machines that offer impressive precision and are often more affordable compared to their larger counterparts.

4.1 out of 5 stars

The CNCTOPBAOS CNC 3018 Pro Max is a high-quality desktop DIY mini wood router kit designed for woodworking enthusiasts and hobbyists. With its 3-axis design, this CNC machine is capable of carving and engraving various materials such as wood, PCB, and PVC with precision and efficiency. The compact size of the cnc router table makes it ideal for use in small workshops or home garages. The kit comes with all the necessary components for easy assembly and setup, allowing users to start creating their projects right away. Whether you are a beginner or experienced user, the CNCTOPBAOS CNC 3018 Pro Max is a versatile and reliable capable machine for all your woodworking needs. just for: $160.99

Another popular option is the gantry-style CNC router. These machines feature a bridge-like structure that spans the work area, providing a stable and rigid platform for cutting. Gantry-style CNC routers are known for their exceptional accuracy and are well-suited for larger woodworking projects, such as cabinet making, furniture production, and sign making. One of the key applications of gantry-style CNC routers is furniture making, which includes creating home and office furniture, cabinets, and decorative items.

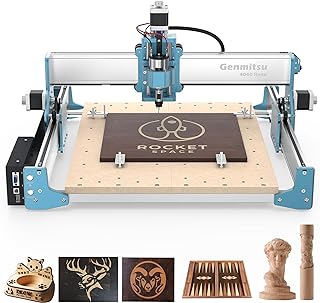

4.6 out of 5 stars

The Genmitsu 4040 Reno CNC Router Milling Machine is a highly versatile tool ideal for both woodworking and acrylic cutting. Featuring a compact design and precision stepper motor, it delivers exceptional performance for both hobbyists and professionals. Its robust frame and powerful spindle ensure reliable and accurate results across various projects. Paired with user-friendly software, this machine excels in carving intricate wood crafts and creating custom acrylic pieces, making it a standout choice for any woodworking shop seeking a blend of reliability and precision. just for: $449.00

Before investing in a CNC router for your woodworking projects, it’s essential to carefully consider several key factors that will guide your decision-making process.

One of the primary factors to consider is the intended use of the CNC router. Are you planning to work on small, intricate projects or larger, more complex pieces? This will help you determine the appropriate size and cutting capacity required for your needs. (Read Best CNC Machine for Small Business)

Another crucial factor is the available workspace in your workshop or studio. Measure the area where you intend to set up the CNC router and ensure that the machine you choose will fit comfortably without compromising your overall workflow.

It is also important to have a suitable power supply that meets the machine’s voltage and amperage needs to ensure proper functionality when starting up the machine.

Additionally, consider the materials you’ll be working with. Different CNC routers are designed to handle various types of wood, from soft, delicate woods (or even plywood) to dense, hard materials. Ensure that the machine you select is a capable machine that can efficiently and safely cut the materials you’ll be using.

The size and capacity of a CNC router are essential factors to consider when selecting the perfect machine for your woodworking projects. The work area, or the maximum dimensions of the material you can cut, is a critical specification to keep in mind.

For smaller projects, such as intricate carvings or delicate furniture pieces, a benchtop CNC router with a compact work area may be sufficient. These models typically have a work area ranging from 12” x 18” to 24” x 36”, making them ideal for hobbyists and small workshops. Visit our wide selection of bench top CNC Routers here.

If you’re working on larger projects, such as cabinetry, signage, or full-size furniture, you’ll need a CNC router with a more expansive work area. Floor-standing or gantry-style CNC routers often offer work areas of 4’ x 8’ or even larger, allowing you to tackle more ambitious woodworking projects with ease. Projects like creating table legs or sofa legs also benefit from the larger work area these machines provide. Get to know our CNC Routers selection here.

It’s important to consider not only the maximum work area but also the machine’s weight capacity. Ensure that the CNC router you choose can handle the weight of the materials you’ll be cutting, as this will ensure the stability and precision of your cuts.

The spindle and cutting capabilities of a CNC router are crucial factors that directly impact the quality and efficiency of your woodworking projects. Understanding these specifications will help you make an informed decision when selecting the right machine.

The spindle is the heart of the CNC router, responsible for rotating the cutting tool and powering the cutting process. The spindle’s speed, measured in revolutions per minute (RPM), is an essential consideration. Higher spindle speeds generally allow for faster and smoother cutting, particularly when working with harder woods or intricate designs.

5.0 out of 5 stars

The RATTMMOTOR CNC Spindle Motor Kit is a high-quality, durable, and efficient spindle motor designed for CNC machines. With a power output of 2.2KW and operating at 220V, this air-cooled spindle motor is perfect for a wide range of machining applications. The square design ensures stability and precision during operation, while the air cooling system helps to prevent overheating and extend the motor's lifespan. This kit includes all necessary components for easy installation and is a reliable choice for both hobbyists and professionals in the CNC machining industry. just for: $298.00

Alongside spindle speed, the power of the spindle motor—particularly a liquid-cooled spindle—plays a vital role. A high-powered spindle motor, especially one with advanced cooling, delivers the necessary torque and cutting force for handling larger and denser materials, ensuring smooth and precise cuts.

The type of cutting tool used in the CNC router is also a significant consideration. Look for machines that offer a wide range of tool sizes and types, such as straight bits, end mills, and V-bits, to accommodate the diverse needs of your woodworking projects. Selecting the appropriate router bit is essential for achieving quality cuts and finishes, as different router bits are designed for specific materials and applications.

Precision and accuracy are paramount when it comes to CNC routing for woodworking projects. The ability of the machine to consistently produce high-quality, repeatable results is essential for achieving professional-grade finishes and seamless fits.

A ball screw is crucial in driving the spindle or router across various axes, offering advantages such as accuracy, reduced backlash, and efficient power transfer, making it a preferred choice for precision woodworking applications.

Besides the technology of the ball screw or any other movement method applied to the cutter, One of the key factors that contribute to precision and accuracy in CNC routing is the machine’s construction and design. Look for CNC routers with a rigid and stable frame, as well as high-quality linear guides and bearings, which help minimize vibrations and ensure smooth, precise movements.

4.4 out of 5 stars

Introducing the All-Metal CNC Router Machine 3020-Evo, featuring AnoleX X&Z-axis Dual Steel Guide Rails for precision and durability. This machine is perfect for hobbyists, small businesses, and DIY enthusiasts looking to create intricate designs with ease. With a sturdy all-metal construction, this CNC router offers reliable performance and smooth operation. The AnoleX X&Z-axis Dual Steel Guide Rails ensure accurate and consistent cuts, while the compact size of the machine makes it ideal for small workspaces. Take your projects to the next level with the All-Metal CNC Router Machine 3020-Evo. just for: $469.00

The control system and software of the CNC router also play a crucial role in achieving precise and accurate cuts. Look for machines with advanced control features, such as closed-loop feedback systems and advanced motion control algorithms, which help compensate for any potential errors or inconsistencies.

Additionally, the calibration and maintenance of the CNC router are critical for maintaining its precision and accuracy over time. Regular checks and adjustments (for each of the Three axes), as well as proper tool maintenance, can help ensure that your machine continues to deliver consistent, high-quality results for your woodworking projects.

The software and control options of a CNC router are essential considerations when selecting the right machine for your woodworking projects. The ease of use, compatibility, and advanced features of the software can significantly impact your overall workflow and productivity.

When evaluating the software and control options, look for CNC routers that offer user-friendly, intuitive interfaces. The ability to easily navigate the software, create and edit designs, and generate G-code (the programming language used to control the machine) can greatly streamline your design and production processes.

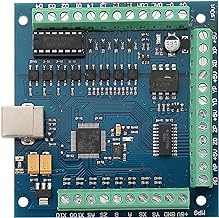

5.0 out of 5 stars

The RATTMMOTOR Mach3 USB CNC Controller Board is a high-performance 4-axis motion control card designed for CNC machines. This controller board is compatible with Mach3 software, allowing for precise and accurate control of your CNC machine. With USB connectivity, it is easy to set up and use, making it ideal for both beginner and experienced users. The compact design and durable construction ensure long-lasting performance, making it a reliable choice for your CNC machining needs. just for: $26.80

Another important factor to consider is the software’s compatibility with your existing design software, such as CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) programs. Seamless integration between these programs and the CNC router’s software can greatly improve your efficiency and reduce the risk of errors.

Additionally, some CNC routers offer advanced control features, such as automatic tool changers, dust collection systems, and remote monitoring capabilities. These features can enhance the overall productivity and efficiency of your woodworking workflows, allowing you to focus on the creative aspects of your projects.

The cost and budget for a CNC router are crucial factors to consider when making your purchase decision. CNC routers can vary widely in price, from affordable benchtop models to high-end, industrial-grade machines.

When determining your budget, it’s essential to consider not only the initial cost of the CNC router but also the ongoing costs associated with its operation and maintenance. This includes the cost of cutting tools, software subscriptions, and any necessary accessories or upgrades.

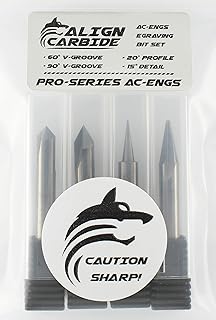

4.6 out of 5 stars

The Align Carbide 4-Piece Engraving Set is a must-have for any woodworking enthusiast or professional. This set includes four high-quality CNC wood carving router bits, each featuring a 60° angle for precise and intricate engraving. Made from durable carbide material, these bits are designed to last through countless projects and provide clean and crisp results every time. Whether you're working on detailed designs or simple lettering, this engraving set is sure to meet your needs and exceed your expectations. Upgrade your woodworking arsenal with the Align Carbide 4-Piece Engraving Set today. just for: $38.95

4.6 out of 5 stars

The Genmitsu 2PCS T-Track Mini Hold Down Clamp Kit is the perfect solution for securing your workpieces during CNC routing on wood and other materials. These compact clamps are designed to fit seamlessly into your T-Track system, providing a secure and reliable hold on your workpiece. With a durable construction and easy-to-use design, these clamps are a must-have accessory for any CNC router user. Keep your materials in place and your projects on track with the Genmitsu T-Track Mini Hold Down Clamp Kit. just for: $19.99

It’s also important to factor in the potential return on investment (ROI) that a CNC router can provide. By increasing productivity, reducing manual labor, and enabling the creation of more complex and intricate designs, a CNC router can potentially pay for itself over time through increased efficiency and profitability.

While it’s tempting to opt for the most affordable option, it’s crucial to strike a balance between cost and the features and capabilities that will best serve your woodworking needs. Carefully evaluate the long-term value and benefits of each CNC router model to ensure that you make a wise investment.

With the wide range of CNC router brands and models available on the market, it’s essential to conduct thorough research and make careful comparisons to find the best fit for your woodworking needs.

Start by identifying the leading CNC router manufacturers in the industry for each category, such as FoxAlien, Genmitsu and Powermatic. Explore their product lines, read reviews, and compare the key specifications and features of their various models.

4.1 out of 5 stars

The FoxAlien CNC Router Machine 4040-XE is a high-quality, compact machine designed for precision engraving and milling. With a powerful 300W spindle and 3-axis control, this machine is perfect for creating intricate designs on a variety of materials including wood, plastic, and metal. The compact size makes it ideal for small workshops or home use, while still offering professional-level results. Whether you're a hobbyist or a professional, the FoxAlien CNC Router Machine 4040-XE is a versatile and reliable tool for all your engraving and milling needs. just for: $899.00

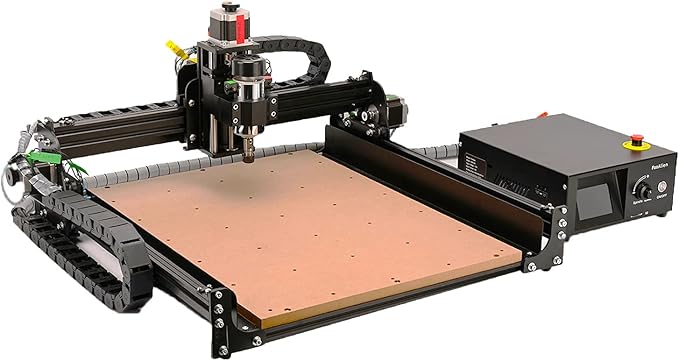

4.0 out of 5 stars

The Powermatic CNC Router Machine with Electro Spindle, 1Ph 220V (Model PM-2X4SPK) is a high-performance machine designed for precision woodworking and cutting applications. This CNC router features a powerful electro spindle that delivers fast and accurate cutting results, making it ideal for professional woodworkers and hobbyists alike. The machine is equipped with a 1-phase 220V motor for reliable and efficient operation. With its advanced technology and user-friendly interface, the Powermatic CNC Router Machine is the perfect choice for creating intricate designs and projects with ease. just for: $11374.54

Pay close attention to the reputation and customer feedback for each brand, as this can provide valuable insights into the reliability, performance, and customer service of the CNC routers. Look for brands with a proven track record of delivering high-quality, durable machines that meet the needs of woodworkers.

Additionally, consider attending woodworking trade shows or visiting local dealers to get hands-on experience with different CNC router models. This can help you better understand the user experience, ease of operation, and overall capabilities of the machines before making a purchase.

After carefully considering all the factors and researching various CNC router brands and models, it’s time to finalize your decision and make the purchase. This final step requires careful deliberation and a thoughtful approach to ensure that you select the perfect CNC router for your woodworking projects.

Begin by revisiting the initial factors you identified as most important, such as the intended use, available workspace, and budget. Ensure that the CNC router you have chosen aligns with these key considerations and will meet your specific needs.

Once you have confirmed that the CNC router is a suitable fit, take the time to thoroughly review the warranty, delivery, and installation options provided by the manufacturer or retailer. This can help you feel confident in your purchase and ensure a smooth transition into using your new CNC router.

Finally, don’t hesitate to reach out to the manufacturer or experienced woodworkers for any additional guidance or support. Their expertise can be invaluable in helping you get the most out of your CNC router and ensuring that you have a seamless and successful woodworking experience.

Feeling stuck on your next move?

📦 Start with a CNC BundleInstant downloads. Trusted files. Real results.