Building your own CNC machine is a significant undertaking that many makers consider. At Agilemaking, we not only built our own CNC machine but discovered key insights that can help you in your CNC machine building journey. If you’re wondering how to build your own CNC machine, our experience offers valuable lessons for your project.

When you decide to build your own CNC machine, working with a partner can significantly impact your success. Our CNC machine building project revealed that teamwork isn’t just helpful – it’s transformative. Here’s what we discovered while building our CNC machine:

Through extensive hands-on experience, we’ve identified that precision measurement tools form the cornerstone of successful CNC machine construction. Let’s examine the two critical categories of tools that ensure build success when building a precision CNC machine capable of 0.1mm accuracy.

The foundation of any accurate CNC build lies in precise measurements. Digital measurement technology like the Bosch GLM165-40 Laser Distance Measure with its 1/16-inch precision, revolutionizes the build process in three key ways:

First, it enables real-time rail alignment verification, allowing immediate adjustments during setup. Second, it ensures consistent measurements across all machine components, eliminating cumulative errors. Third, it facilitates quick modifications during assembly, saving time while maintaining accuracy.

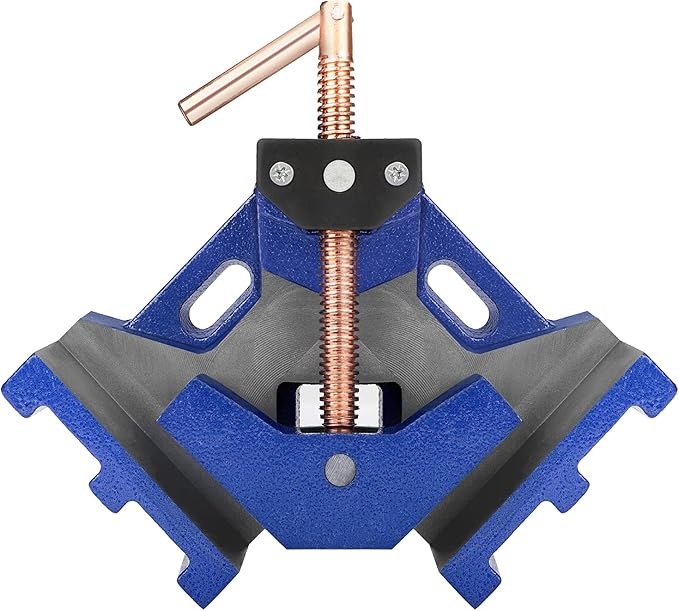

Achieving and maintaining perfect 90-degree angles represents another crucial aspect of CNC machine construction. A comprehensive approach combines three essential tools: a professional machinist square for precise alignment verification, a heavy-duty cast iron welder’s angle clamp for maintaining angles during assembly, and a robust 14-inch quick-change chop saw for precise component cutting.

What makes these tools particularly valuable is their complementary nature. The digital precision of modern measurement tools works alongside traditional precision instruments to provide both rapid measurements and absolute verification. This dual approach proves essential when working with tolerances measured in hundredths of a millimeter (0.1mm precision).

Consider this practical example: during rail alignment, even a fraction of a degree off square compounds across the machine’s travel, potentially resulting in significant positioning errors. By using both digital and traditional measurement tools, we can catch and correct these deviations before they affect the machine’s performance. This attention to detail during construction directly translates to the precision of the finished CNC machine.

For more information about precision tool selection and use, check out our detailed guide on choosing the right CNC tools and accessories and understanding CNC machines.

The satisfaction of achieving that perfect 90-degree cut, verified by multiple precision tools, might seem like excessive attention to detail. However, when building a machine designed to make movements precise to fractions of a millimeter, this level of accuracy becomes not just desirable but essential for successful operation. This systematic approach to measurement and verification during construction establishes the foundation for a highly precise and reliable CNC machine.

Our approach to building a CNC machine focused on stability and functionality. We chose a fixed-bridge design with a moving bed for several reasons:

I’ll never forget the moment we first powered up the servo motors and watched the bed move smoothly along its rails. That’s when we knew our attention to detail during the build was paying off. The phenolic plywood bed was particularly clever – it’s tough enough to handle heavy work but forgiving enough to allow for modifications as our needs change.

Looking at our completed machine now, it’s hard not to feel a bit proud. Every challenge we overcame, every problem we solved together, contributed to creating something that works better than we initially hoped. The teamwork aspect really can’t be overstated – there were moments of frustration, sure, but having someone there to share both the challenges and the victories made the whole process not just manageable, but genuinely enjoyable.

Want to chat more about CNC building? Got questions about specific aspects of our build? Join our mailing list at [email protected] for detailed guides, pro tips, and build discussions. Our experienced team shares regular updates on CNC building, from precision components to advanced techniques.

Before you start your CNC build, consider these fundamental tools:

For the Bosch laser measure:

4.7 out of 5 stars

Professional grade laser measure with 165ft range, backlit display, and real-time measurement capability. Features accuracy within 1/16 inch and multiple measurement modes for precise distance calculations.

For the welding square clamp:

4.6 out of 5 stars

Heavy-duty 90-degree cast iron angle clamp for precise welding and soldering work. Features a sturdy design with reinforced corners for maximum stability and accuracy in metalworking projects.

4.8 out of 5 stars

High-precision engineer's square made from hardened steel with ground and lapped faces. Features a 100x70mm working surface and provides excellent perpendicularity for setup and measurement tasks. Perfect for metalworking, woodworking, and precision alignment applications.

4.7 out of 5 stars

Professional-grade 14-inch metal cutting saw with quick-change wheel release system. Features a powerful 15-amp/4,000-watt motor, ergonomic D-shaped handle, and 45-degree pivoting fence for precise angle cuts. Quick-lock vise ensures secure material clamping for accurate cutting results.

At Agilemaking, we’re not just talking theory – we’ve been through the CNC building journey ourselves, and we bring that hands-on experience to everything we do. Whether you’re building your own machine or looking for CNC design services, we get it, because we’ve been there.