Are you considering adding a new CNC machine to your workshop but feeling overwhelmed by the price tags? You’re not alone. Many makers, small business owners, and hobbyists find themselves wondering if a CNC machine is a feasible addition to their toolkit. In this comprehensive guide, we’ll break down the price range of CNC machines, explore what factors influence their cost, including software, installation, and accessories, and help you determine if it’s a worthwhile investment for your specific needs.

Before we dive into pricing, let’s quickly define what we’re talking about:

A CNC machine is a computer-controlled power tool that uses computer numerical control (CNC) to perform various machining operations.

CNC machines are used in various industries, including woodworking, metalworking, and manufacturing.

They offer high precision, accuracy, and efficiency in machining processes.

When it comes to the cnc machine price, there’s a vast range to consider. From budget-friendly options for home shops to industrial-grade machines for large-scale manufacturing, the cost can vary significantly. Different types of CNC machines cater to different needs and applications, which in turn influences their upfront costs. Let’s break it down:

Price Range: $150 – $450

These affordable CNC machines are perfect for hobbyists, beginners, and small businesses just starting out. They often include:

CNC routers

Small CNC milling machines

DIY CNC kits

While they may have limitations in terms of size and materials they can work with, these machines offer a great introduction to CNC technology without breaking the bank.

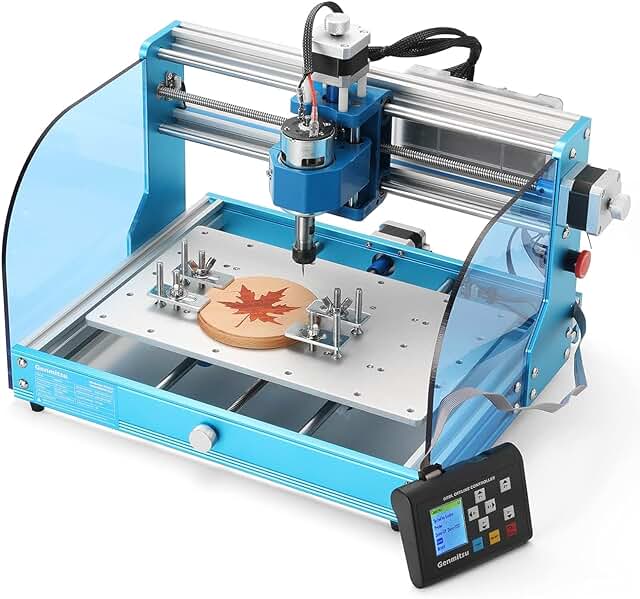

Affordable Precision

Engineered for precise and stable operations, the Genmitsu 3018-PROVer offers a perfect blend of affordability and performance.

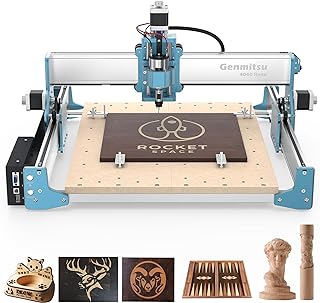

The perfect tool for bringing your creative projects to life

The Genmitsu 4040 Reno CNC Router Milling Machine stands out with its precision and versatility, allowing for intricate woodworking and acrylic cutting projects.

Price Range: $450 – $10.000

These machines offer a balance between affordability and capability, suitable for small to medium-sized businesses and serious hobbyists. You’ll find:

More robust CNC milling machines

CNC routers with larger work areas

Some CNC lathes

High Resistant for Heavy Duty

Built with industrial grade components, the Shark HD520 also features a heavy-duty aluminum and steel reinforced gantry, a new extruded aluminum router mount system, interlocking aluminum table, linear rails and guides on the gantry, and anti-backlash, wear-compensated lead screws on all axis.

Easy to operate. It can work with 3 axis / 4 axis / 5 axis

Independent drivers for each axis. Mach 3 software USB connection Upgraded with more stable structure

Mid-range machines often come with more features, such as higher precision, faster cutting speeds, and the ability to work with a wider range of materials.

Price Range: $10.000+

At this level, you’re looking at machines designed for professional shops and manufacturing facilities. These include:

High-end CNC milling machines

CNC machining centers with multiple axes

Industrial CNC lathes

For craftspeople who strive for perfection with each project

The unparalleled design of these machines will give you the confidence, flexibility and durability needed to make even your biggest dream project a reality.

Powerful 4.75 HP spindle

2 ft. x 3 ft. CNC router table for metal. Up to 18,000 RPM variable spindle speed

These machines offer top-tier precision, speed, and the ability to handle complex projects and tough materials like steel.

Several factors contribute to the wide range of CNC machine prices, collectively referred to as cnc machine cost. These factors include machine complexity, features, and the intended audience. Understanding the specific requirements and the range of costs associated with different types of CNC machines, from hobbyist models to professional-grade machines, is crucial when assessing the price of CNC machines.

Larger machines with bigger table sizes generally cost more.

The work envelope (X, Y, Z coordinates) of a CNC machine impacts its price.

Consider how much space you have and the size of projects you’ll typically work on.

The number of axes (3, 4, or 5 axis CNC mills vs 2 axis or more lathe) affects the price.

More axes make a machine more powerful, but also more complex and expensive.

Features like high-speed spindles and automatic tool changers increase costs.

Higher machining accuracy often comes with a higher price tag.

For some projects, micron-level precision is crucial, while others may not require such exactness.

Machines designed to work with harder materials like metals will generally be more expensive than those primarily for wood or plastics.

Established CNC machine manufacturers often charge more, but this can come with better reliability, support, and resale value. The reputation of a cnc machine manufacturer plays a crucial role in determining the overall cost of the machine. Buyers should consider the brand’s history of providing robust after-sales support and the quality of sample making when selecting the right type and model for their specific requirements.

When budgeting for a CNC machine, remember that the initial purchase price isn’t the whole story. Other costs to factor in include the CNC control system, which is essential for both hobbyist and professional-grade machines. While the CNC control system is often included in basic CNC setups, its integration can vary significantly across different types of machines. Additionally, consider expenses for software and other necessary integrations.

Cutting tools can cost several thousand dollars

Consumables like lubricants and coolants add to ongoing costs

Milling vises, chucks, calipers, and micrometers are necessary

These can add several thousand dollars to your investment

CAD/CAM software licenses

Costs for integrating the CNC machine with existing systems

Power supply upgrades

Dust collection systems

Regular maintenance is crucial for keeping your CNC machine in optimal condition and preventing costly breakdowns. This includes routine tasks such as lubrication, cleaning, and replacing worn parts. Depending on the complexity of your machine, you may need to budget for professional maintenance services or train your staff to perform these tasks. Additionally, even with proper maintenance, unexpected repairs can occur. It’s wise to set aside a contingency fund for potential repair costs, which can include replacing major components like spindles or control boards. The cost of maintenance and repairs can vary widely but could easily run into thousands of dollars annually for a professional-grade machine.

Investing in proper training for operators and programmers is essential to maximize the efficiency and longevity of your CNC machine. This may involve formal training courses offered by the machine manufacturer or third-party providers, which can cost several hundred to a few thousand dollars per person. Additionally, consider ongoing education to keep up with new technologies and techniques. Online resources, textbooks, and subscriptions to industry publications can also add to your learning budget. For businesses, there may be costs associated with developing internal training programs or creating documentation specific to your operations. While these expenses may seem significant upfront, they are crucial for ensuring safe operation, minimizing errors, and maximizing the productivity of your CNC investment.

These additional costs can add up, sometimes equaling 20-30% of the machine’s purchase price over the first year.

To determine if a CNC machine is a worthy investment for your workshop, consider the following:

Calculate how much time the machine could save you

Estimate the potential increase in production capacity

Consider new product lines or services you could offer

Learn more about ROI here.Be prepared to invest time in learning G-code, CAD/CAM software, and machine operation

Ensure you have enough room not just for the machine, but also for material storage and workflow around it

If you’re running a business, will a CNC machine help you take on new clients or expand your offerings?

Are you frequently turning down jobs because you can’t achieve the necessary precision or complexity by hand?

When buying a CNC machine, you have the option of buying new or used:

New CNC machines offer the latest technology and features but can be more expensive.

Used CNC machines can be a cost-effective option but may require maintenance and repairs.

We will be writing more about this soon, so stay tuned to Agilemaking blog!

Financing options are available for CNC machines, including loans and leasing:

Consider the total cost of ownership, including financing costs, when making your decision.

Research and compare financing options to find the best deal for your business.

Look, investing in a CNC machine isn’t just about buying a piece of equipment – it’s about unlocking a world of possibilities for your craft or business. Sure, the upfront cost might make you think twice, but here’s the thing: a good CNC machine can be a game-changer. It’s not just about what it can do today; it’s about how it can transform your work tomorrow. Think about the precision you’ll achieve, the time you’ll save, and the new projects you’ll be able to tackle. Before you know it, that machine could be paying for itself by boosting your productivity and opening doors to opportunities you haven’t even imagined yet. It’s an investment in your future, really.

But, at the end of the day, the decision to invest in a CNC machine is highly personal and depends entirely on your situation. I encourage you to sit down and make an honest analysis of your business or project. Get out a pen and paper, and start crunching the numbers. Consider not just the initial cost of the machine, but all those extra expenses we’ve mentioned: maintenance, tools, software, training. Now, think about your market. What new opportunities could you seize with this tool? How would it improve your production? Do you have the contacts or the ability to generate the business necessary to justify this investment? Don’t fool yourself; be realistic with your projections. Remember, what works for others might not be ideal for you. Take the time to evaluate your skills, your market, and your long-term goals.

This isn’t just about buying a machine; it’s about shaping the future of your work. Only you can decide if the potential benefits outweigh the costs and risks for your unique situation. Who knows? This could be the tool that takes your passion from a hobby to a thriving business.

Ready to explore CNC machines further? Check out our curated selection of CNC tools and accessories to complement your future machine!

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!