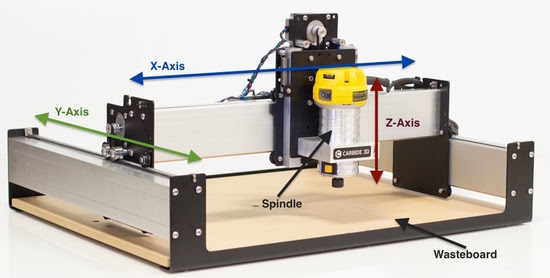

This is the Shapeoko from Carbide 3D.

This style of machine is known as a “gantry-style CNC”. It has a wide, open work area that makes it easy to lay down larger pieces of material. A moving gantry design is optimized for a large work area relative to the overall size of the machine.

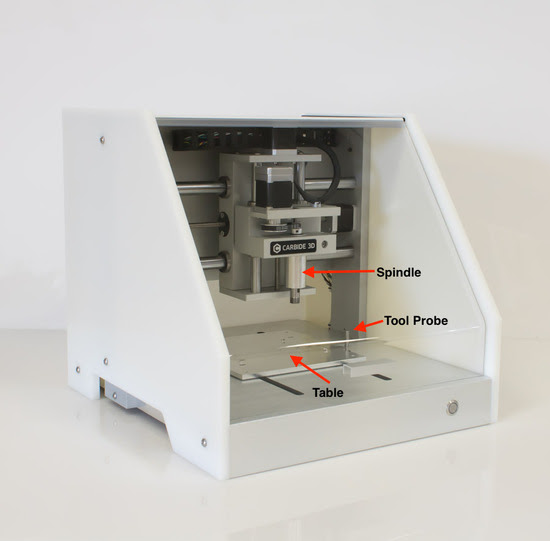

This is the Nomad CNC machine from Carbide 3D.

The Nomad is known as a moving-table style machine that is optimized for rigidity and accuracy. On the Nomad, the table moves in the Y direction, while the fixed gantry moves in the X and Z directions. The Nomad also has a custom spindle (instead of the trim router shown on the Shapeoko) and an integrated tool probe, which measures the length of your tool.

Y-Axis If you’re standing in front of the machine, the Y-axis is the part that moves forward and backwards. In the case of a CNC Router likeShapeoko, the Y-axis responsible for moving the entire gantry.

(Some people refer to the Y-axis as ‘the gantry’. For the sake of being correct, you need to know that the gantry is actually the entire assembly, not just the Y-axis!)

X-Axis This is the part of the CNC machine that moves left and right (when looking at the machine from the front). The X axis is generally driven by one motor, and is responsible for carrying the Z-Axis around the machine.

Z-Axis The business end of your CNC machine! The Z-axis carries the spindle, and is responsible for raising and lowering your cutting tool to the correct height. One important feature to look for in a good Z-axis is how much travel it has. More travel allows you to use longer tools and makes it easier to perform tool changes.

Spindle Your workhorse! The spindle is the tool you are using to turn your end mills (bits). You can use anything from a basic rotary tool, to a purpose build 15hp water cooled spindle designed specifically for high performance machining. In the hobby and prosumer range, a quality trim router is a great choice.

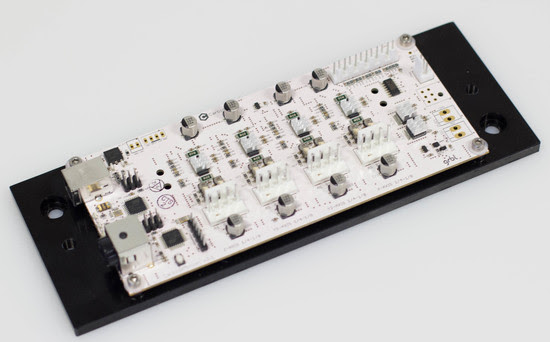

The Brains The controller provides the link between your computer and your CNC machine. Most modern machines, especially in the hobby, prosumer, and home use, prefer connection via USB, so no special computer is required to connect to the controller.

Software

To a lot of people, this is the scary part. With terms like CAD/CAM, G-Code_, and machine control software_, it’s easy to get intimidated. FEAR NOT! Here’s what each one means.

Machine Controller

This is the software that allows you to operate your CNC machine. The machine control software gives you the ability to turn your machine on and off, load your G-Code, jog your machine, and set your job zero point. Think of the machine controller as the cock-pit of the CNC machine! One of most famous control software is MACH3.

CAD (Computer Aided Design)

CAD is where you turn your idea into a digital design. CAD is software that allows you to draw on your computer. This can be anything from a full blown parametric 3D modeling package like Solidworks, or Fusion 360 to something as simple as Adobe Illustrator. Don’t let the word CAD scare you. All it means is ‘a program to draw in’.

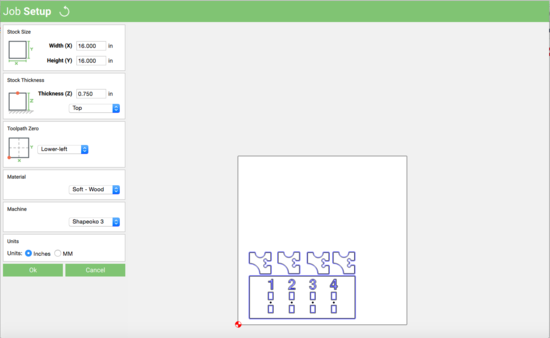

CAM (Computer Aided Manufacturing) CAM is where you turn your CAD design into something your CNC machine can understand. CAM is software that lets you specify HOW your design is going to be made on your CNC machine. Your CAM program will output G-Code. Like most terminology around CNC, CAM sounds scarier than it really is.

G-code If Spanish is ‘the language of love’, then G-code is ‘the language of manufacturing’. G-code is a set of instructions for your machine that tell it things like where to go, how fast to move, to turn the spindle on and off, along with a host of other actions.

Although possible, you never have to write G-Code directly! 99% of people never even look at the G-Code file their CAM program produces. We only bring it up so you know what people are talking about when they say ‘G-code’.

Summary

In summary, we have explored the key concepts and specific vocabulary of the CNC, CAD, and CAM niche with the aim of providing you with a solid foundation to approach future projects with confidence and efficiency. We hope that this information enables you to successfully advance in your machining and design projects, making the most of the technologies and tools available in this constantly evolving field.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!

Leave a Reply