From intricate furniture designs to detailed signage, woodworking has been transformed by the advent of Computer Numerical Control (CNC) routers. These precision machines have revolutionized the industry, offering increased efficiency, accuracy, and versatility for both small workshops and large manufacturing facilities.

Using advanced software and cutting-edge technology, CNC routers streamline the woodworking process. They can effortlessly create complex shapes and patterns, ensuring consistent quality and reducing human error. These routers are capable of engraving, carving, and cutting a wide range of materials, including wood, plastic, and even metal, making them indispensable in various industries.

Whether you’re a professional woodworker or a DIY enthusiast, CNC routers offer endless possibilities. Their ability to effortlessly handle intricate designs and replicate them with precision is unparalleled.

The origins of CNC (Computer Numerical Control) routers in the woodworking industry can be traced back to the 1950s. As technology advanced, woodworkers began to explore ways to automate and streamline their processes, moving away from the traditional hand-operated tools that had dominated the craft for centuries.

In the early days, CNC routers were large, bulky machines that required significant floor space and were primarily used in industrial settings. These early CNC systems were controlled by punched tape or rudimentary computer programs, offering limited flexibility and precision compared to modern-day counterparts. However, as computer technology evolved, so too did the capabilities of CNC routers, making them increasingly accessible and practical for use in woodworking workshops of all sizes.

By the 1980s, the introduction of user-friendly software and more affordable hardware allowed CNC routers to gain traction in the woodworking community. Hobbyists and small-scale woodworkers began to embrace these versatile machines, recognizing their potential to enhance productivity, improve accuracy, and unlock new creative possibilities. As the technology continued to advance, CNC routers became more compact, powerful, and cost-effective, making them an essential tool in the modern woodworking landscape.

At the heart of a CNC router is a computer-controlled cutting tool that can precisely carve, engrave, or cut a wide range of materials, including wood, plastic, and even metal. The process begins with the creation of a digital design using specialized CAD (Computer-Aided Design) software. This design is then converted into a set of instructions, known as G-code, which the CNC router can interpret and execute.

The CNC router’s cutting tool, typically a high-speed spindle or drill bit, is programmed to follow the precise movements and patterns specified in the G-code. The machine’s computer-controlled motion system, consisting of stepper motors or servo motors, precisely controls the position and movement of the cutting tool, ensuring accurate and consistent results.

The material to be worked on is securely clamped onto the CNC router’s work table, which can be programmed to move in multiple axes (typically X, Y, and Z) to facilitate complex cutting and engraving operations. As the cutting tool follows the predetermined path, it removes material from the workpiece, creating the desired shape or design. This process is highly automated, allowing CNC routers to produce intricate and complex designs with unparalleled precision and repeatability.

The integration of CNC technology into the woodworking industry has brought about a host of benefits that have revolutionized the way professionals and hobbyists approach their craft. Here are some of the key advantages of using CNC routers in woodworking:

Increased Precision and Accuracy: CNC routers are renowned for their ability to produce consistent, high-quality results with exceptional precision. By eliminating human error and variability, these machines can create intricate designs, complex shapes, and delicate details that would be challenging or even impossible to achieve with traditional hand tools.

Enhanced Productivity and Efficiency: CNC routers automate many of the repetitive and time-consuming tasks associated with woodworking, such as cutting, carving, and engraving. This automation allows woodworkers to complete projects more quickly and with less manual effort, significantly improving their overall productivity.

Versatility and Design Flexibility: CNC routers are capable of working with a wide range of materials, from solid wood to plastics and even metals. This versatility enables woodworkers to explore new creative possibilities and expand their product offerings. Additionally, the digital design process allows for easy modifications and customizations, making CNC routers an invaluable tool for prototyping and small-batch production.

While CNC routers have undoubtedly revolutionized the woodworking industry, their applications extend far beyond the realm of wood. These versatile machines have found a wide range of uses in various other industries, showcasing their adaptability and the far-reaching impact of this technology.

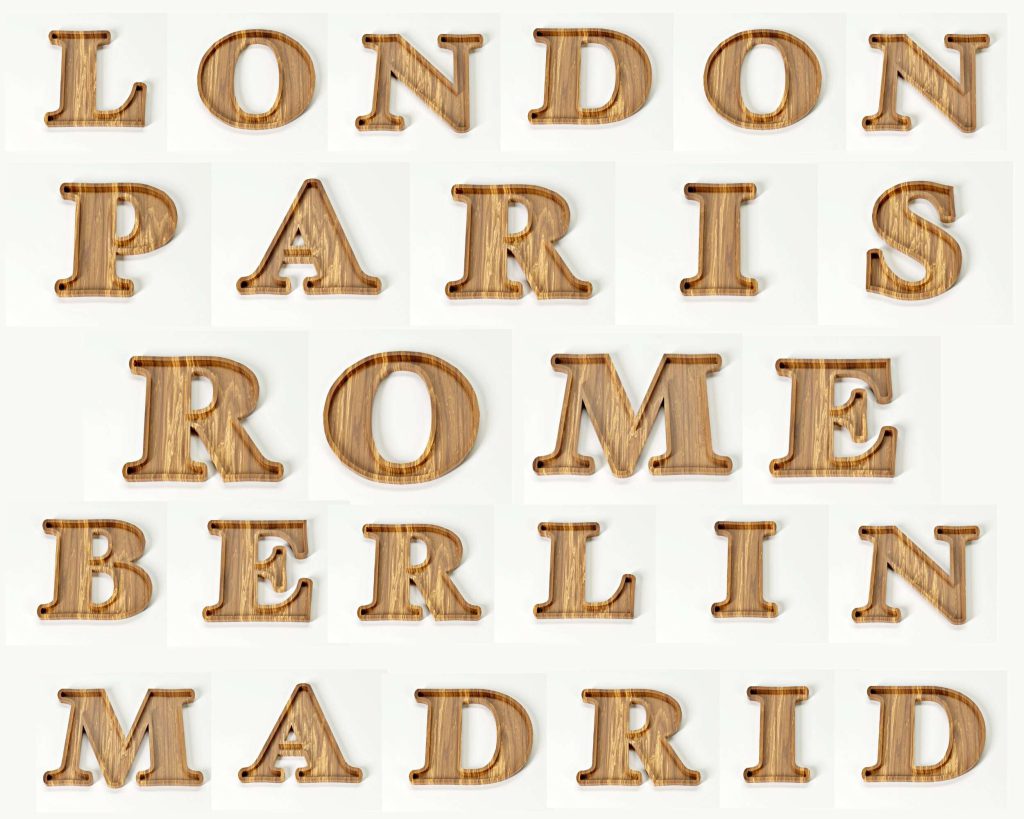

Signage and Engraving: CNC routers have become an indispensable tool in the signage and engraving industry. Their ability to precisely carve and engrave a variety of materials, including wood, acrylic, and even metal, has made them a go-to solution for creating high-quality, custom-made signs, plaques, and other decorative elements.

Our CNC Letter Boards are a collection of intricately designed wood templates compatible with wood routers. Each file in this set contains a unique router typeface that allows you to create stunning alphabet-inspired grill planks for your BBQ gatherings. Transform your outdoor cookouts with these finely crafted designs, making your BBQ experience truly one-of-a-kind. Moreover, imagine crafting …

Architectural and Construction: In the architectural and construction sectors, CNC routers are used to fabricate intricate building components, such as decorative moldings, custom-shaped architectural elements, and even entire sections of structures. Their precision and versatility allow for the creation of complex designs that would be challenging or impossible to achieve using traditional methods.

Aerospace and Automotive: CNC routers have also found applications in the aerospace and automotive industries, where they are used to manufacture components and prototypes with exceptional accuracy. From the production of custom-designed dashboard panels to the fabrication of intricate aircraft parts, these machines have become an integral part of the manufacturing process in these high-precision industries.

When it comes to selecting the right CNC router for your woodworking or other industrial needs, there are several factors to consider to ensure you make an informed decision that aligns with your specific requirements.

Machine Size and Workspace: One of the primary factors to consider is the size of the CNC router and the available workspace. Determine the maximum dimensions of the workpieces you need to accommodate, and choose a machine with a work area that can comfortably handle your projects. Larger workspaces offer more flexibility, but they also require more physical space in your workshop or facility.

Power and Spindle Capabilities: The power and spindle capabilities of a CNC router are crucial, as they determine the machine’s cutting speed, depth, and the range of materials it can handle. Consider the types of materials you’ll be working with, the level of detail required, and the desired production speed to select a CNC router with the appropriate power and spindle specifications.

Precision and Accuracy: Depending on your specific needs, the level of precision and accuracy required may vary. If you’re working on intricate designs or need to maintain tight tolerances, look for CNC routers with advanced motion control systems and high-quality components that can deliver the necessary level of precision.

While CNC routers offer numerous benefits, it’s essential to prioritize safety when operating these powerful machines. Proper safety protocols and precautions must be in place to ensure the well-being of both the operator and the surrounding environment.

Operator Training and Certification: Ensure that all operators of the CNC router have received comprehensive training on the safe and proper use of the machine. This includes understanding the machine’s capabilities, programming, and maintenance, as well as the implementation of safety protocols. Consider requiring operators to obtain relevant certifications to demonstrate their competence.

Guarding and Shielding: CNC routers should be equipped with appropriate guarding and shielding mechanisms to protect the operator from moving parts, flying debris, and potential hazards. This may include safety enclosures, transparent guards, and emergency stop buttons that can quickly halt the machine’s operation in case of an emergency.

Dust and Noise Control: CNC routers can generate significant amounts of dust and noise during operation. Ensure that the machine is installed in a well-ventilated area and that appropriate dust collection systems are in place to maintain a safe and healthy work environment. Additionally, consider the use of noise-reducing measures, such as sound-dampening enclosures, to protect the operator and nearby personnel.

To ensure the long-term reliability and optimal performance of your CNC router, it’s essential to implement a comprehensive maintenance and troubleshooting regimen. Proper care and attention can extend the machine’s lifespan, minimize downtime, and prevent costly repairs.

Preventive Maintenance: Establish a regular maintenance schedule that includes tasks such as cleaning the machine, lubricating moving parts, and inspecting critical components for wear or damage. Regularly calibrating the machine’s axes and checking for accuracy can help maintain precision and consistent output.

Troubleshooting Techniques: When issues arise, have a systematic approach to troubleshooting the problem. This may involve checking for software or firmware updates, verifying electrical connections, and inspecting mechanical components for any abnormalities. Maintain detailed records of any problems encountered and the steps taken to resolve them, as this information can be invaluable for future reference.

Spare Parts and Inventory Management: Keep a well-stocked inventory of essential spare parts, such as cutting tools, bearings, and control system components. This will allow you to quickly address any breakdowns or malfunctions, minimizing downtime and ensuring your CNC router is always ready for operation.

As technology continues to evolve, the future of CNC routers holds exciting possibilities that will further transform the woodworking and broader manufacturing industries. Here are some of the emerging trends and anticipated developments in CNC router technology:

Increased Automation and Integration: The integration of advanced automation and AI-powered technologies will continue to enhance the capabilities of CNC routers. This may include the development of self-adjusting systems, automated tool changers, and intelligent error-detection mechanisms that can optimize the production process and minimize human intervention.

Advancements in Material Processing: As materials science advances, CNC routers are expected to expand their capabilities in working with a wider range of materials, including advanced composites, high-performance plastics, and even harder metals. This will open up new possibilities for product design and manufacturing across various industries.

Improved Connectivity and Data Analytics: The integration of CNC routers with IoT (Internet of Things) technologies and cloud-based platforms will enable seamless data collection, remote monitoring, and predictive maintenance. This connectivity will provide valuable insights into machine performance, productivity, and overall efficiency, allowing for data-driven decision-making and continuous process improvement.

The advent of CNC routers has undoubtedly transformed the woodworking industry, ushering in a new era of precision, efficiency, and creative possibilities. These versatile machines have not only revolutionized the way woodworkers approach their craft but have also found applications in a wide range of industries, from signage and architecture to aerospace and automotive manufacturing.

By offering unparalleled accuracy, enhanced productivity, and design flexibility, CNC routers have empowered both professionals and hobbyists to push the boundaries of what is achievable in the realm of woodworking and beyond. The integration of advanced technologies, such as automation and data analytics, promises even more exciting developments in the future, further solidifying the indispensable role of CNC routers in shaping the manufacturing landscape.

As the industry continues to evolve, the impact of CNC routers will only continue to grow, driving innovation, improving quality, and expanding the creative potential of those who harness the power of these remarkable machines. Whether you’re a seasoned woodworker or an entrepreneur exploring new manufacturing opportunities, understanding the capabilities and potential of CNC routers is crucial for staying ahead in an ever-changing, technology-driven world.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!