In today’s fast-paced world of product development, virtual prototyping has become an indispensable tool. It helps businesses save time, reduce costs, and streamline the design process. Fusion 360’s simulation features are a testament to the power of virtual prototyping.

With Fusion 360, designers and engineers can visualize, validate, and optimize their designs before investing in physical prototypes. This powerful software allows users to run simulations that mimic real-world conditions, providing valuable insights into how a product will perform under various scenarios.

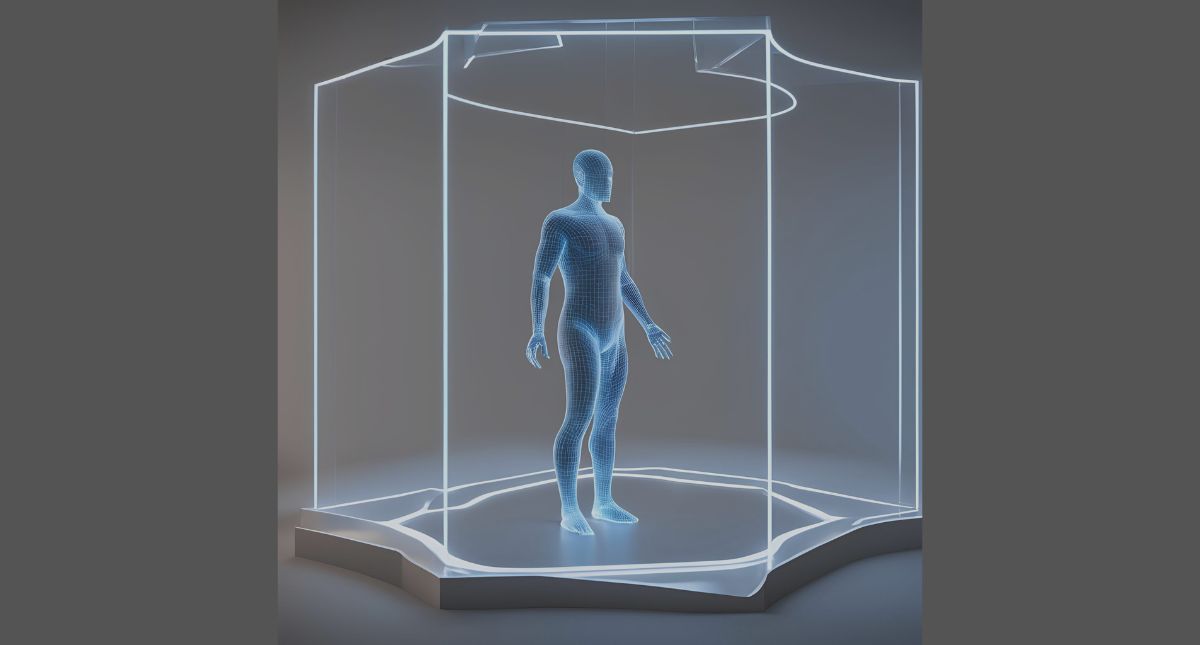

Virtual prototyping is the process of creating and testing digital models of products before investing in physical prototypes. This approach allows designers and engineers to simulate real-world scenarios, identify potential issues, and refine their designs without the time and cost associated with building physical prototypes. By leveraging advanced computer-aided design (CAD) and simulation software, virtual prototyping enables a more efficient and iterative product development process.

At the heart of virtual prototyping is the ability to create digital replicas of products that can be subjected to a wide range of tests and analyses. These digital models can be manipulated, stressed, and evaluated in a virtual environment, providing valuable insights into the performance, durability, and functionality of the product. This allows for early detection and resolution of design flaws, ultimately leading to better-quality products and a more streamlined development timeline.

Virtual prototyping is particularly beneficial for complex products or systems that require extensive testing and validation. By simulating various operating conditions, designers can identify potential failure points, optimize product performance, and ensure compliance with industry standards and regulations. This approach not only reduces the number of physical prototypes required but also enables more thorough testing and evaluation, leading to more robust and reliable products.

One of the primary advantages of virtual prototyping is the ability to save time and reduce costs in the product development process. By identifying and addressing design issues early on, companies can avoid the time and expense of building physical prototypes, which can be both labor-intensive and resource-intensive. This allows for a more agile and iterative design process, where changes and refinements can be made quickly and efficiently.

Another significant advantage of virtual prototyping is the ability to explore a wider range of design options and scenarios. In a physical prototyping approach, the number of variations and test cases is often limited by the available resources and time constraints. With virtual prototyping, designers can quickly and easily create and evaluate multiple design iterations, enabling them to explore a broader design space and identify the most optimal solution.

Virtual prototyping also enhances collaboration and communication among the various stakeholders involved in the product development process. By creating shareable digital models, designers can easily share their work with colleagues, clients, and manufacturing partners, facilitating better understanding, feedback, and decision-making. This collaborative approach can lead to more informed design decisions and a more streamlined development process.

Furthermore, virtual prototyping allows for the simulation of real-world conditions and scenarios that would be difficult or expensive to replicate in a physical setting. This includes testing products under extreme environmental conditions, simulating product interactions with other systems, and evaluating the impact of manufacturing processes on product performance. By gaining this deeper understanding of product behavior, designers can make more informed decisions and create products that are better suited to the intended use cases.

Fusion 360, a powerful cloud-based CAD/CAM/CAE software, offers a comprehensive suite of simulation tools that enable virtual prototyping. With Fusion 360’s simulation features, designers and engineers can analyze and validate their designs before investing in physical prototypes.

One of the key simulation capabilities in Fusion 360 is the ability to perform structural analysis. This allows users to apply loads, constraints, and boundary conditions to their digital models, simulating real-world stresses and deformations. By understanding how the product will behave under various loading scenarios, designers can optimize the design for strength, durability, and reliability.

In addition to structural analysis, Fusion 360 also provides fluid flow simulation tools. These tools enable users to simulate the behavior of fluids, such as air or water, interacting with their product designs. This can be particularly useful for applications like aerodynamic analysis, fluid dynamics, and thermal management, helping designers to optimize the product’s performance and efficiency.

Fusion 360’s simulation capabilities extend beyond structural and fluid flow analysis. The software also offers thermal simulation, which allows users to assess the thermal behavior of their designs, including heat transfer, temperature distribution, and thermal stresses. This is especially important for products that operate in high-temperature environments or require effective thermal management.

Setting up a simulation in Fusion 360 is a straightforward process that involves several key steps. First, the user must create a digital model of the product or component they want to simulate. This can be done using Fusion 360’s powerful CAD tools, which provide a wide range of modeling capabilities to create accurate and detailed representations of the design.

Once the digital model is created, the user can select the type of simulation they want to perform, such as structural analysis, fluid flow, or thermal simulation. Fusion 360 provides a user-friendly interface that guides the user through the simulation setup process, allowing them to define the necessary parameters, such as materials, loads, boundary conditions, and mesh settings.

The next step is to define the simulation scenario, which involves specifying the environmental conditions, loading cases, and any other relevant factors that will be applied to the digital model. This step is crucial in ensuring that the simulation accurately reflects the real-world conditions the product will encounter.

After the simulation scenario is defined, Fusion 360 will automatically generate a mesh, which is a discretized representation of the digital model. The mesh quality is critical for the accuracy of the simulation results, and Fusion 360 provides various tools to optimize the mesh and ensure reliable simulation outcomes.

Once the simulation setup is complete, the user can initiate the simulation process. Fusion 360’s powerful computational capabilities allow the software to quickly and efficiently perform the necessary calculations, providing the user with detailed results and visualizations that can be used to analyze the product’s performance and identify potential areas for improvement.

Fusion 360 offers a wide range of simulation capabilities, each designed to address specific design and engineering challenges. By understanding the different types of simulations available, users can leverage the full potential of the software to optimize their product development process.

One of the most commonly used simulation types in Fusion 360 is structural analysis. This simulation allows users to assess the structural integrity of their designs by applying various loads, stresses, and boundary conditions. Structural analysis can help identify potential failure points, optimize material usage, and ensure the product’s overall durability and reliability.

Another powerful simulation capability in Fusion 360 is fluid flow analysis. This simulation allows users to model the behavior of fluids, such as air or water, as they interact with the product design. This can be particularly useful for applications like aerodynamic optimization, HVAC system design, and cooling system development, where understanding fluid dynamics is crucial.

Fusion 360 also offers thermal simulation, which enables users to analyze the thermal performance of their designs. This includes evaluating heat transfer, temperature distribution, and thermal stresses. Thermal simulation is essential for products that operate in high-temperature environments or require effective thermal management, such as electronic devices, automotive components, and industrial equipment.

In addition to these core simulation types, Fusion 360 also provides more specialized simulation capabilities, such as modal analysis, which can help identify the natural frequencies and vibration modes of a product, and electromagnetic simulation, which can be used to analyze the electromagnetic properties of electronic components and circuits.

Interpreting the results of simulations performed in Fusion 360 is a crucial step in the virtual prototyping process. The software provides a wealth of data and visualizations that allow users to gain a deep understanding of how their product designs will perform under various conditions.

One of the key aspects of interpreting simulation results is the ability to identify potential areas of concern or failure. By analyzing the stress, strain, and deformation patterns displayed in the simulation results, designers can pinpoint the regions of the product that are most vulnerable to failure or underperformance. This information can then be used to make targeted design improvements, such as reinforcing weak points, adjusting material properties, or modifying the overall product geometry.

Fusion 360’s simulation results also provide valuable insights into the product’s performance characteristics, such as its strength, stiffness, and thermal behavior. By analyzing these metrics, designers can optimize the design to meet specific performance requirements, ensuring that the final product delivers the desired functionality and meets the needs of the target market.

Another important aspect of interpreting simulation results is the ability to compare multiple design iterations. Fusion 360 allows users to save and compare simulation results, enabling them to quickly identify the most optimal design solution. This comparative analysis can reveal the trade-offs between different design choices, allowing designers to make informed decisions that balance performance, cost, and other critical factors.

Fusion 360’s simulation capabilities have a wide range of real-world applications across various industries, demonstrating the power and versatility of virtual prototyping.

In the automotive industry, Fusion 360’s simulation features are used to optimize the design of vehicle components, such as suspension systems, engine mounts, and body panels. By simulating the forces and stresses these components will experience during operation, designers can ensure they meet safety and performance standards, while also optimizing weight and material usage to improve fuel efficiency and reduce manufacturing costs.

In the aerospace industry, Fusion 360’s fluid flow and thermal simulation capabilities are used to analyze the aerodynamic performance of aircraft and spacecraft designs. This allows engineers to optimize the shape and configuration of the airframe, as well as the performance of critical systems like avionics, propulsion, and environmental control, all within a virtual environment before committing to physical prototypes.

The consumer electronics industry also benefits from Fusion 360’s simulation features, particularly in the design of electronic devices and their thermal management systems. By simulating the heat dissipation and airflow patterns within a device, designers can ensure that critical components remain within safe operating temperatures, preventing performance degradation or premature failure.

In the medical device industry, Fusion 360’s simulation capabilities are used to evaluate the structural integrity and biomechanical performance of implants and prosthetic devices. This allows designers to optimize the design for patient comfort, functionality, and long-term durability, all while minimizing the need for physical testing and prototyping.

To maximize the benefits of Fusion 360’s simulation features, it’s important to follow a set of best practices that ensure accurate and reliable results.

One of the most crucial best practices is to ensure the accuracy and fidelity of the digital model being simulated. This means creating a detailed and representative model that accurately captures the geometry, materials, and other relevant properties of the physical product. Neglecting to do so can lead to simulation results that do not accurately reflect the real-world performance of the product.

Another best practice is to carefully define the simulation scenario, including the appropriate boundary conditions, loads, and environmental factors. This step requires a deep understanding of the product’s intended use and the conditions it will encounter in the real world. Failing to accurately represent these factors can result in simulation results that do not accurately predict the product’s performance.

Effective mesh generation and optimization is also a critical best practice for using Fusion 360’s simulation capabilities. The mesh quality directly impacts the accuracy and reliability of the simulation results, so it’s essential to invest time in creating a well-designed mesh that captures the relevant features and details of the digital model.

Finally, it’s important to validate the simulation results by comparing them to physical testing data or industry-standard benchmarks. This helps to ensure that the simulation is accurately predicting the product’s performance and provides a basis for making informed design decisions. Regularly validating simulation results can also help identify areas where the simulation process can be improved or refined.

In today’s fast-paced and competitive business environment, virtual prototyping has become an indispensable tool for product development. Fusion 360’s comprehensive suite of simulation features empowers designers and engineers to harness the power of virtual prototyping, enabling them to create better products, faster and more cost-effectively.

By leveraging Fusion 360’s simulation capabilities, users can visualize, validate, and optimize their designs before investing in physical prototypes. From structural analysis and fluid flow simulation to thermal modeling and modal analysis, Fusion 360 provides a wide range of tools that allow users to explore a broader design space, identify potential issues, and make informed design decisions.

The real-world applications of Fusion 360’s simulation features span a diverse range of industries, from automotive and aerospace to consumer electronics and medical devices. By simulating the performance of their products under various conditions, designers and engineers can ensure that their designs meet the necessary performance, safety, and reliability standards, all while reducing the time and cost associated with physical prototyping.

To maximize the benefits of Fusion 360’s simulation capabilities, it’s essential to follow best practices, such as creating accurate digital models, defining appropriate simulation scenarios, and validating the simulation results. By adopting these practices, users can unlock the full potential of virtual prototyping and stay ahead in the competitive landscape.

In conclusion, Fusion 360’s simulation features are a game-changer in the world of product development. By harnessing the power of virtual prototyping, designers and engineers can streamline their workflow, reduce costs, and bring better products to market faster than ever before. If you’re looking to stay ahead of the curve, embracing Fusion 360’s simulation capabilities is a strategic move that can truly transform your product development process.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!