Imagine increasing your CNC shop’s productivity while significantly reducing your environmental footprint. Thanks to advancements in automation, AI-powered CNC programming, and energy-efficient machines, this vision is now a reality for manufacturers worldwide.

🚀 Pro Tip: Implementing Industry 4.0 strategies won’t just make you more competitive—it will position you as a leader in smart and sustainable CNC manufacturing.

Artificial intelligence (AI) and the Internet of Things (IoT) are transforming how CNC shops operate. From optimizing tool paths to predictive maintenance, AI-powered automation provides numerous benefits:

✅ Key Advantages of CNC Automation

🔧 Example: A CNC manufacturer implementing AI-based monitoring systems saw a 30% reduction in production downtime while improving energy efficiency.

4.2 out of 5 stars

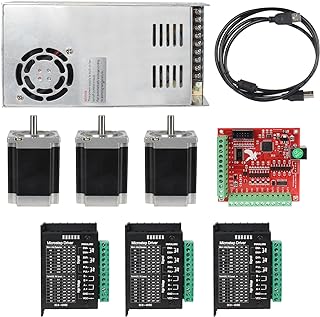

Upgrade your CNC system with the RATTMMOTOR CNC Controller Kit. Includes Nema23 stepper motors for precise control. Ideal for DIY enthusiasts and small businesses.

Sustainability is a growing priority in CNC manufacturing. Companies are implementing solutions like:

4.7 out of 5 stars

Precision cutting, high-volume production, smooth and accurate cuts – perfect for professionals and hobbyists.

Many CNC shops are adopting solar power and energy-efficient CNC controllers to reduce their carbon footprint. Advanced energy management systems track usage and optimize machine performance.

💡 Example: A mid-sized CNC manufacturer integrated solar power and AI-driven energy management, cutting electricity costs by 40% in the first year.

Imagine CNC machines that communicate with each other, monitor processes in real time, and make autonomous decisions. That’s the power of a smart factory.

🚨 Mistake To Avoid: Don’t underestimate the power of digitization. Companies that fail to adopt smart manufacturing technologies risk falling behind competitors who leverage AI, IoT, and automation.

Implementing CNC automation software and cloud-based monitoring systems can lead to:

To future-proof your CNC shop, start with these steps:

3.7 out of 5 stars

Enhance your CNC machine with our high-performance CNC Spindle Kit. Featuring a 220V 2.2KW air-cooled spindle motor for reliable precision and stability.

Before upgrading, consider:

🚀 Quick Solution: Start your journey to smart manufacturing by conducting an audit of your shop to identify areas for automation and sustainability improvements.

Industry 4.0 is already transforming CNC shops worldwide. By embracing automation and sustainability, you won’t just improve efficiency—you’ll become a leader in next-generation CNC manufacturing.

📢 What’s Next? How are you preparing your CNC shop for the future? Share your thoughts in the comments!

🔗 Explore more insights on CNC automation and sustainability at Agilemaking.com.

🔗 Explore more insights on CNC automation and sustainability at Agilemaking.com.

🛠️ If you’re looking to integrate Industry 4.0 solutions into your CNC workflow, check out our CNC Programming Services—we specialize in optimizing toolpaths, automating processes, and enhancing efficiency with cutting-edge software solutions.