CNC manufacturing, which stands for Computer Numerical Control manufacturing, is a revolutionary process that uses computerized controls to operate and manipulate machine and cutting tools to shape stock material—such as metal, plastic, wood, foam, and composites—into custom parts and designs. This advanced technology has transformed the manufacturing industry, offering unparalleled precision, efficiency, and versatility.

CNC technology has come a long way since its inception in the 1940s and 1950s. Initially developed for the aerospace industry, CNC machines have become increasingly accessible and user-friendly, paving the way for their adoption in small businesses, workshops, and even households. Today, CNC machining is used across various industries, from automotive and aerospace to electronics and medical devices.

At the heart of CNC machining is the intricate dance between computer programming and mechanical engineering. Here’s a deeper look into the process:

Design Creation: The process begins with creating a digital design using Computer-Aided Design (CAD) software. This 3D model serves as the blueprint for the part to be machined.

CAM Processing: The CAD model is then processed using Computer-Aided Manufacturing (CAM) software. This step translates the design into a series of machine-readable instructions, typically in a language called G-code.

Machine Setup: The CNC machine is prepared by loading the appropriate tools, securing the workpiece, and inputting the G-code program.

Machining Process: Once started, the CNC machine follows the programmed instructions to cut and shape the material. This can involve various operations such as milling, turning, drilling, or even 3D printing in some advanced machines.

Quality Control: After machining, the part is inspected to ensure it meets the specified dimensions and quality standards.

The world of CNC machines is diverse, with each type designed for specific applications. Let’s explore some of the most common types in more detail:

CNC routers are versatile machines primarily used for cutting, carving, and engraving various materials, including wood, plastic, and soft metals. A CNC router excels in creating intricate 2D and 3D designs, making them popular among woodworkers, sign makers, and furniture manufacturers.

Key Features:

Large work areas suitable for sheet materials

Multiple axis movement for complex 3D carving

Various spindle options for different materials and applications

5.0 out of 5 stars

The Genmitsu CNC Router Machine PROVerXL 4030 is a versatile and powerful tool for woodworking, metalworking, acrylic cutting, and MDF carving. With a large cutting area of 400 x 300 mm, this machine is perfect for both small and large projects. Its sturdy construction and high precision make it ideal for professional and hobbyist users alike. The machine is easy to assemble and use, with intuitive software that allows for precise and intricate designs. Whether you're a seasoned craftsman or just starting out, the Genmitsu CNC Router Machine PROVerXL 4030 is sure to meet all your carving and cutting needs. just for: $978.99

CNC milling machines are powerhouses in the world of metal fabrication. They use rotating cutting tools to remove material from a workpiece, creating complex shapes and features.

Key Features:

High precision and accuracy

Ability to work with hard materials like steel and titanium

Various configurations (vertical, horizontal, 5-axis) for different applications

4.8 out of 5 stars

The CNC 5 axis router 3040 Ovsuqu mini CNC milling machine is a high-quality, precision tool designed for small-scale machining and carving projects. With a powerful 2.2KW motor, this machine is capable of cutting a wide range of materials with ease and accuracy. The 5 axis design allows for intricate and complex shapes to be created with precision and efficiency. Whether you are a hobbyist or a professional, this CNC milling machine is perfect for creating detailed and intricate designs in a compact and versatile package. just for: $3250.00

Desktop CNC machines bring the power of CNC technology to a compact form factor. These machines are perfect for hobbyists, small businesses, and educational institutions looking to explore CNC machining without the need for a large industrial setup.

Key Features:

Compact size suitable for home workshops or small offices

User-friendly interfaces and software

Affordable entry point into CNC machining

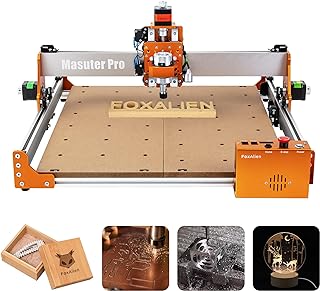

4.1 out of 5 stars

Introducing the FoxAlien Masuter Pro CNC Router Machine, the ultimate tool for precision engraving and cutting. This upgraded 3-axis machine is made with all-metal construction for durability and stability. With a powerful spindle motor and high-speed cutting capabilities, the Masuter Pro can handle a wide range of materials with ease. Perfect for hobbyists, DIY enthusiasts, and small businesses, this CNC router machine offers professional-grade results at an affordable price. Take your projects to the next level with the FoxAlien Masuter Pro CNC Router Machine. just for: $649.00

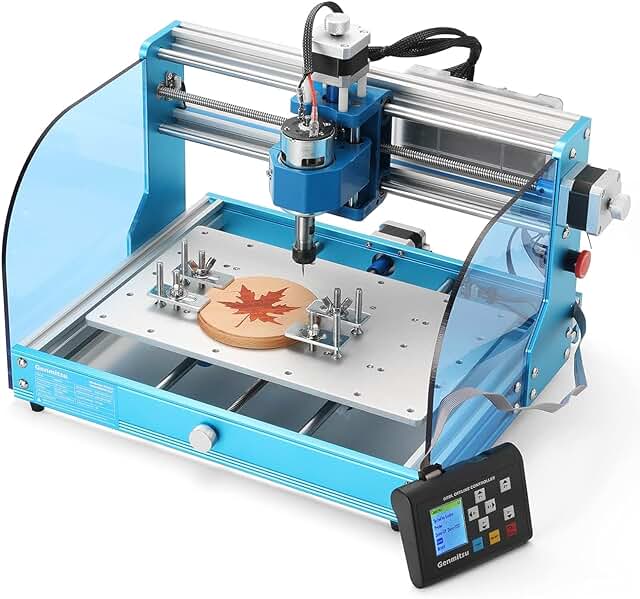

4.2 out of 5 stars

The Genmitsu 3018-PROVer V2 CNC Router Machine is the perfect tool for beginners looking to get started with milling and engraving projects. This mini machine is compact yet powerful, allowing you to create intricate designs with ease. With its upgraded features, including a more stable structure and improved performance, this CNC router is ideal for hobbyists, DIY enthusiasts, and small businesses. Whether you're working on wood, plastic, acrylic, or even soft metals, the Genmitsu 3018-PROVer V2 can handle it all. Start bringing your creative ideas to life with this versatile and user-friendly CNC router. just for: $269.00

All-in-one CNC machines, like the Snapmaker Artisan 3 in 1, offer a versatile solution for those looking to explore multiple manufacturing processes. These machines typically combine CNC routing, 3D printing, and laser engraving capabilities in a single unit.

Spotlight on Snapmaker Artisan 3 in 1:

The Snapmaker Artisan 3 in 1 is an excellent example of how CNC technology is becoming more accessible and versatile for household use. This machine offers:

CNC Routing: Capable of cutting and carving a wide range of materials with precision.

3D Printing: Allows for additive manufacturing, opening up new possibilities for prototyping and small-scale production.

Laser Engraving: Enables detailed engraving and cutting on various materials.

4.1 out of 5 stars

The Snapmaker Artisan 3D Printer is a versatile and powerful tool for all your 3D printing needs. With dual extrusion capabilities, you can create intricate and detailed designs with ease. The large 3D printing area allows you to print bigger and more complex projects. Whether you're a hobbyist, designer, or engineer, the Snapmaker Artisan is the perfect choice for bringing your ideas to life in stunning detail. just for: $1,599.00

Key advantages of the Artisan 3 in 1 include:

Versatility: Combines multiple manufacturing processes in one machine, saving space and resources.

User-Friendly Design: Engineered for ease of use, making it accessible to beginners and experts alike.

Expandability: Offers options for upgrades and add-ons, allowing the machine to grow with your needs.

Community Support: Backed by a strong community of users, providing resources and support for new users.

For households and small businesses looking to explore CNC technology, the Snapmaker Artisan 3 in 1 presents an attractive all-in-one solution that balances capability, affordability, and ease of use.

The advantages of CNC machining extend far beyond precision and efficiency. Let’s delve deeper into the benefits:

Unparalleled Precision: CNC machines can achieve tolerances as tight as ±0.001 inches, ensuring consistent quality across production runs.

CNC machining delivers high quality results through advanced machine features, particularly focusing on aspects like rigidity and precision, which contribute to exceptional performance in various applications.

Increased Productivity: Once programmed, CNC machines can operate continuously, significantly reducing production time compared to manual machining.

Complex Geometries: CNC technology enables the creation of intricate designs that would be impossible or extremely difficult to achieve through manual machining.

Material Versatility: From woods and plastics to metals and composites, CNC machines can work with a wide range of materials.

Reduced Waste: The precision of CNC machining minimizes material waste, making it more cost-effective and environmentally friendly.

Repeatability: CNC machines can produce identical parts over and over, ensuring consistency in mass production.

Safety: By automating the machining process, CNC technology reduces the risk of injuries associated with manual machining.

Selecting the ideal CNC machine for your household or small business requires careful consideration of several factors:

Project Requirements: Consider the types of projects you’ll be working on. Are you primarily working with wood, or do you need the ability to machine metals? CNC machines can handle a wide array of tasks, ranging from cutting and drilling to engraving, thus catering to different project requirements.

Work Area: Determine the size of the parts you’ll be creating and ensure the machine’s work envelope can accommodate them.

Precision Needs: Different machines offer varying levels of precision. Assess whether your projects require ultra-high precision or if standard tolerances are sufficient.

Budget: CNC machines range from budget-friendly desktop models to high-end industrial units. Set a realistic budget that accounts for not just the machine, but also tooling, software, and materials.

Ease of Use: If you’re new to CNC machining, look for machines with user-friendly interfaces and robust support resources.

Versatility: Consider machines that offer multiple functions, like the Shapeoko Artisan 3 in 1, if you want to explore various manufacturing processes.

Software Compatibility: Ensure the machine is compatible with CAD/CAM software you’re familiar with or willing to learn.

Support and Community: Look for machines backed by strong manufacturer support and active user communities, which can be invaluable resources as you learn and grow.

Embarking on your CNC machining journey can be exciting and rewarding. Enter the exciting world of CNC machining, where creativity and growth opportunities abound with the right beginner-friendly CNC machine. Here are some steps to get you started:

Learn the Basics: Start with online tutorials, courses, or workshops to understand the fundamentals of CNC machining, CAD, and CAM software.

Start Small: Begin with simple projects to familiarize yourself with the machine and software before moving on to more complex designs.

Practice Safety: Always follow proper safety procedures, including wearing appropriate personal protective equipment (PPE) and ensuring proper ventilation.

Join a Community: Engage with online forums, local makerspaces, or user groups to connect with other CNC enthusiasts and learn from their experiences.

Experiment with Materials: Try working with different materials to understand their properties and how they interact with various cutting tools.

Maintain Your Machine: Regular maintenance is crucial for keeping your CNC machine in top condition. Follow the manufacturer’s guidelines for cleaning, lubrication, and calibration.

Even with proper maintenance, you may encounter issues with your CNC machine. Here are some common problems and solutions:

Poor Surface Finish: This can be caused by incorrect feed rates, spindle speeds, or dull cutting tools. Adjust your machining parameters and ensure your tools are sharp.

Dimensional Inaccuracies: Check for loose belts, backlash in lead screws, or incorrect tool offsets. Regular calibration can help maintain accuracy.

Vibration and Chatter: Ensure your workpiece is securely clamped and your cutting tools are properly tightened. You may need to adjust your cutting parameters or use a more rigid tooling setup.

Software Communication Issues: Keep your machine’s firmware and control software up to date. Check your connections and ensure your computer meets the software’s system requirements.

Tool Breakage: This can be caused by excessive cutting forces or incorrect tool selection. Review your machining parameters and ensure you’re using the appropriate tools for your material and operation.

CNC machining has revolutionized manufacturing, bringing precision and efficiency to businesses of all sizes. With the advent of user-friendly machines like the Shapeoko Artisan 3 in 1, this technology is now more accessible than ever to households and small workshops.

Whether you’re a hobbyist looking to explore new creative possibilities, a small business owner aiming to boost production capabilities, or an educator preparing students for the future of manufacturing, CNC machining offers a world of opportunities. By understanding the basics, choosing the right machine for your needs, and committing to continuous learning, you can harness the power of CNC technology to bring your ideas to life with unprecedented precision and efficiency.

Remember, the journey into CNC machining is one of continuous learning and improvement. Embrace the challenges, celebrate the successes, and don’t hesitate to seek help from the vibrant community of CNC enthusiasts. With patience and perseverance, you’ll soon be creating amazing projects that showcase the true potential of CNC technology.

Discover the World of CNC with Us! We're here to make your journey into CNC and making as smooth as possible. Whether you're a seasoned pro or just starting out, our goal is to provide you with fast navigation and clear guidance to help you find exactly what you're looking for. If you're new to the terminology, don't worry – we've got you covered! Check out our handpicked selection of products on Amazon, where you can find the perfect fit for your needs. And remember, when you make a purchase through our Amazon affiliate links, Agilemaking may receive commissions as compensation.

Happy exploring!

At AgileMaking.com, we focus on providing high-quality resources and content related to Computer Numerical Control (CNC). We strive to understand the needs of our community and offer customized solutions that drive excellence in digital manufacturing. We work collaboratively with our users to ensure long-term success in their CNC projects and operations.

Happy to have you here! Stay in the know with the latest trends, gain insights from our experts, and discover insider tips by making the AgileMaking Blog a regular stop. We’re genuinely excited to be your trusted resource as you explore the boundless possibilities of CNC and making. Welcome aboard, and enjoy the journey!